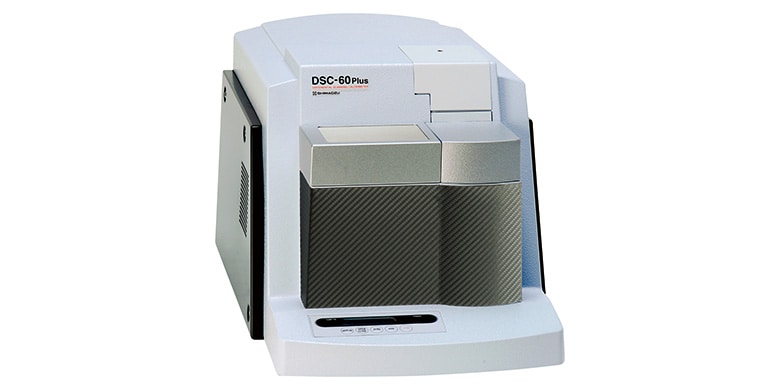

DSC-60 Plus Series

- Use of evaluation techniques that obtained linearity with respect to the material input ratio makes it possible to predict the compounding ratios of unknown materials. - In comparison with a single control criterion, multifaceted evaluation is effective for reducing the risk of erroneous judgments.

Polycarbonate (PC)/acrylonitrile-butadiene-styrene (ABS) resin is a thermoplastic resin with the added heat resistance and impact resistance of PC resin and the moldability and plating characteristics of ABS resin. Because of these properties, it is widely used in automotive interior parts, OA equipment, household electrical appliances, and various other products. Its properties can also be modified to meet various requirement specifications by changing the composition ratio of the PC/ABS resins. Since injection molding is complexly affected by multiple factors such as kneading, temperature, and pressure, the compounding ratio of materials input to the molding machine does not necessarily agree with the composition ratio after molding. For this reason, adjustment of the input compounding ratio during the production process to obtain the molded product with the intended composition ratio is extremely important. Here, the relationship between the compounding ratio and various properties was evaluated using five types of PC/ABS test specimens molded with different compounding ratios of PC and ABS (PC : ABS = 0 : 100, 25 : 75, 50 : 50, 75 : 25, 100 : 0). The agreement of the compounding ratios and the composition ratios after molding was also evaluated. In addition, scanning probe microscope (SPM) measurements were carried out for microscopic observation of the distribution of the component polymers.

24 de octubre de 2023 GMT

Some products may be updated to newer models