Nexera Organic Acid Analysis System - Features

Proprietary Detection Method

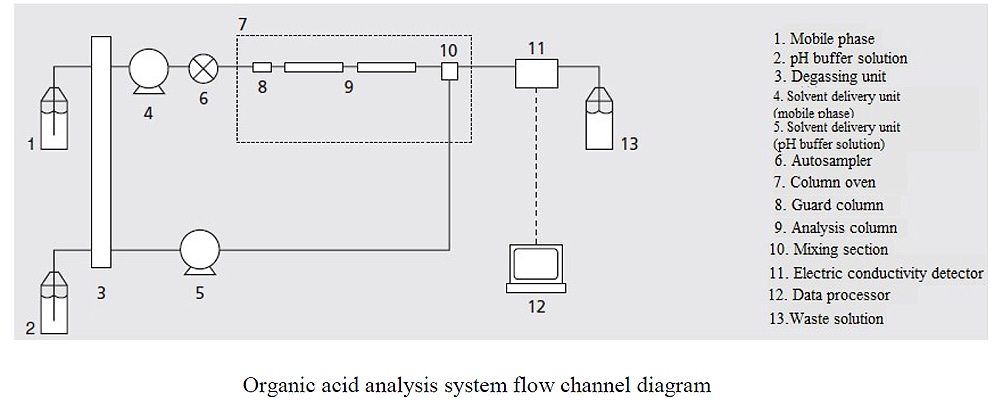

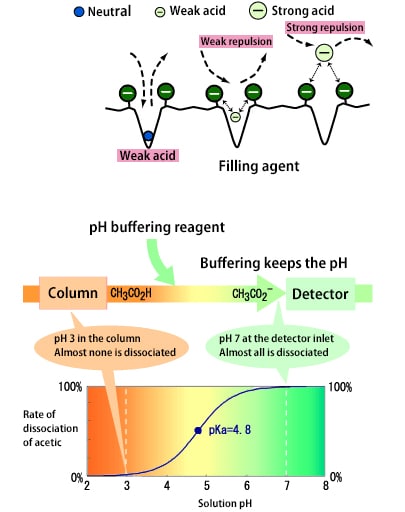

The organic acid system is a highly selective high-sensitivity system. In this system, organic acids are separated using ion exclusion chromatography via Shimadzu’s unique detection technique (pH-buffered electric conductivity detection). Then, a pH-buffering reagent is continuously added to the column eluate in order to keep the pH level at around neutral and dissociate organic acids in order to detect electric conductivity.

In ion exclusion mode, utilized in organic acid analysis, an H+ cation exchange resin is used as the filling agent. Organic acid, the target component, is separated by the magnitude of Donnan exclusion between the stationary phase surface of the H+ cation exchange group and the mobile phase. In this mode, because of the negative charge on the stationary phase, strong acids experience large electrostatic exclusion, and cannot permeate into the filling agent pores. With organic acids and other weak acids, however, the extent of permeation into the pores is determined by the size of this charge, producing a difference (separation) in elution times. Citric acid and lactic acid, which have a large negative charge (small pKa), experience more electrostatic exclusion than acetic acid, and are eluted faster. In principle, organic acids are all eluted up to the elution position for neutral substances (the position at which the pores are completely permeated), with elution ordered from smallest to largest pKa.

Ensures Highly Reliable Analysis Regardless of Operator Skill Level

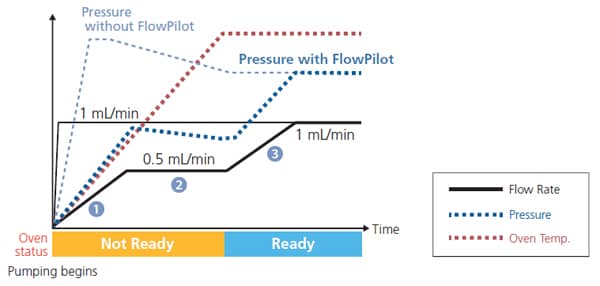

Protects Expensive GPC Columns: FlowPilot

HPLC columns can be damaged by sudden pump starts and stops or extreme gradient changes. The Nexera automatically uses FlowPilot (Smart Flow Control) to increase the flow rate gradually to the set point. There is no need to create startup protocols for each analysis.

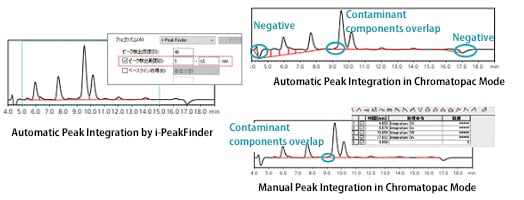

Simplifying Peak Integration: i-PeakFinder Automatic

Peak Integration Algorithm

If organic acids in samples such as alcoholic drinks are analyzed with an electric conductivity detector, negative peaks from the alcohol will be detected, increasing the peak integration processing time. Also, if peak integration is performed manually, not only will the process be labor-intensive, but there is a risk that the results will differ depending on the analyst. The i-PeakFinder algorithm was developed in response to these issues as an improvement on the traditional peak integration (Chromatopac mode). It reduces the complexity of peak integration as well as the risk of human error.

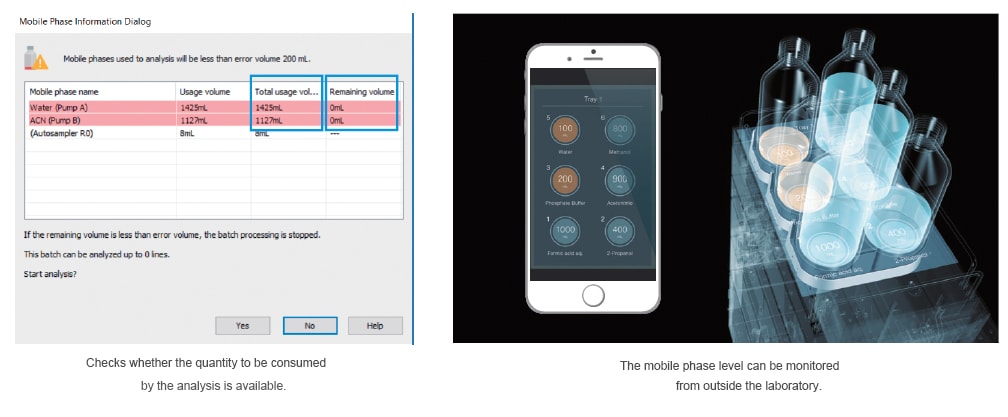

Mobile Phase Levels Measured in Real Time

Reservoir tray weight sensors (optional) can be used to monitor the volume of mobile phase or autosampler rinse solution in up to twelve containers. The containers can also be checked remotely from a smart device. You will no longer need to worry about running out of mobile phase mid-analysis, because the device will notify you before starting the run if the volume remaining is too low.

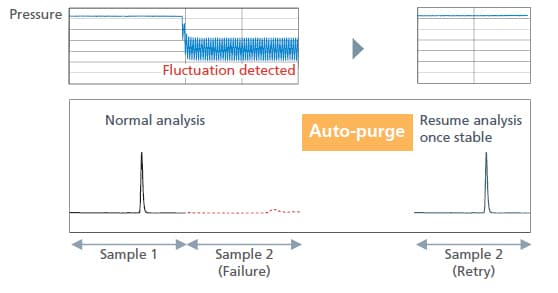

Auto-Diagnostics and Recovery

In rare cases, air bubbles can form in the mobile phase and cause problems if inhaled into the pump. The Nexera has the ability to monitor baseline changes and pressure fluctuations to check for abnormalities. When it detects an unusual fluctuation, it can automatically pause the analysis, purge the flow path, and restart analysis once it has confirmed recovery to normal pressure.

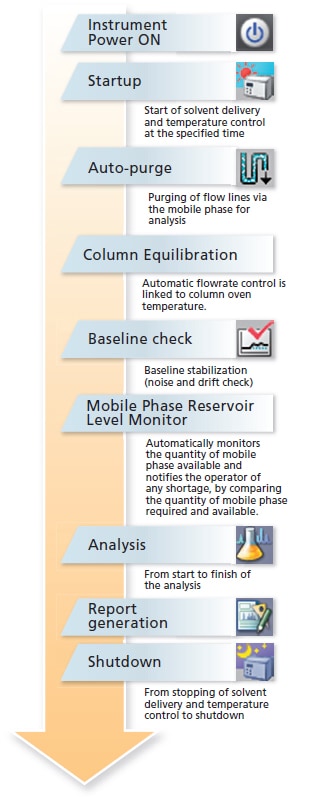

Automated Workflow

Automated support functions throughout the analytical workflow, from instrument startup to shutdown, significantly increases work efficiency. FlowPilot mobile phase flowrate control functionality is linked to column oven temperature, so that columns are protected during automatic column equilibration. Automatic checks for baseline drift maintain instrument stability even in unattended operation.

ANALYTICAL INTELLIGENCE

- Automated support functions utilizing digital technology, such as M2M, IoT, and Artificial Intelligence (AI), that enable higher productivity and maximum reliability.

- Allows a system to monitor and diagnose itself, handle any issues during data acquisition without user input, and automatically behave as if it were operated by an expert.

- Supports the acquisition of high-quality, reproducible data regardless of an operator’s skill level for both routine and demanding applications.