USF-2000A - Specs

Ultrasonic Fatigue Testing System

Specifications

| Test frequency | 20 kHz ±500 Hz (recommended test range: 20 kHz ±30 Hz) Note: The test frequency is determined from the resonance frequency of the sample. |

|---|---|

| Vibration at horn tip | ±10 to ±50 μm |

| Test stress range | Stress given ±10 to ±50 μm displacement of sample Note: Stress values depend on sample shape and physical property values. |

| Stress ratio | -1 |

| Testable materials | Materials that can be resonated at 20 kHz and generate minimal heat during resonance Example: High-strength steel, duralumin, titanium alloy, aluminum, etc. |

| Not-testable materials | - Materials that cannot resonate at 20 kHz - Materials for which samples are difficult to attach - Materials that generate significant heat during resonance at 20 kHz, due to friction Examples: Resins, ceramics, etc. |

| Power Requirements | 3-phase 200 V: 2 kVA (air compressor) , 1-phase 200V: 3.5 kVA (ultrasonic fatigue testing system) , 1-phase 100V: 1 kVA (computer, displacement logger, air dryer, etc.) |

| Standard contents | USF-2000A Ultrasonic Fatigue Testing System main unit (including table), ultrasonic resonance system, control computer,ultrasonic testing control and measurement software, and cooling unit (air dryer and compressed air lines) Note: Air compressor for cooling is not included. |

| Required optional products | Air compressor (for regions with 50 Hz or 60 Hz power) 3-phase 200 V: 2 kVA |

| Displacement measuring system (eddy current displacement gauge with 0.5 μm resolution) Note: A high-speed data logger or digital oscilloscope is required separately for reading voltages output from the displacement gauge. |

|

| Displacement gauge calibrator (CDE-25 C1 high-performance micrometer) |

Note: Systems can be selected without an air compressor in cases where the customer will supply the compressed air. A 150 L/m flow rate of compressed air at a minimum 0.2 MPa is required.

Example of Sample Dimensions (given Young's modulus of 206,000 MPa and density of 7.85 g/cm3)

-

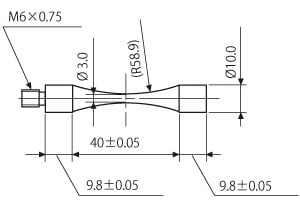

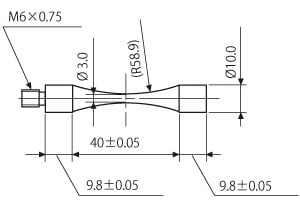

Circular Tapered Sample

Test stress range: About 200 to 1000 MPa nominal

-

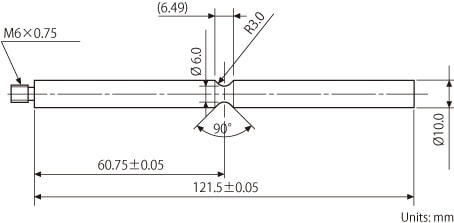

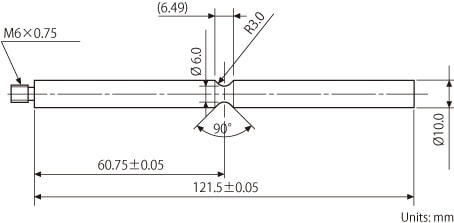

Notched Sample

Test stress range: About 140 to 700 MPa nominal

Stress concentration factor: About 1.56