SPM-Nanoa - Options

Scanning Probe Microscope/Atomic Force Microscope

Nano 3D Mapping™ Fast

—Fast Physical Property Mapping—

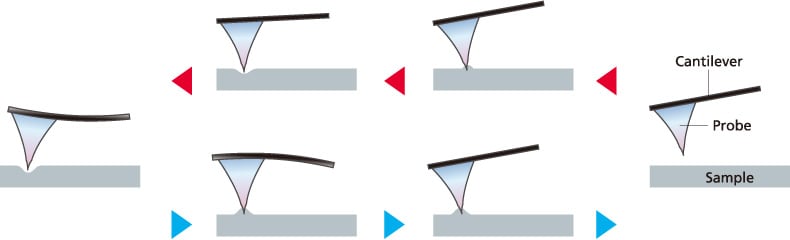

The mechanical properties of materials can be evaluated by measuring the force (force curve) acting on the cantilever probe as its distance from the sample surface is varied.

The faster measurement system enables high-speed mapping of physical properties.

Force Curve Measurement

Cantilever Responses to Forces During Force Curve Measurements

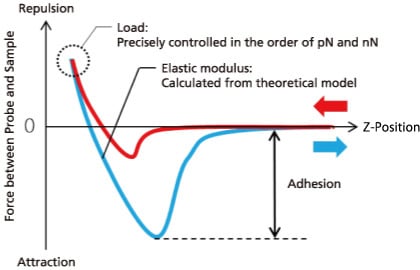

Force Curve

By acquiring a force curve at various points on the sample surface, the physical properties in the XY-plane can be mapped.

This is especially useful for evaluating the mechanical properties of thin films that are difficult to measure even with a nanoindenter or soft materials with a hardness between about a few kPa and 1 GPa.

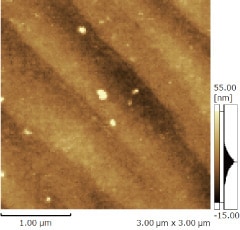

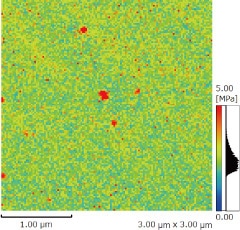

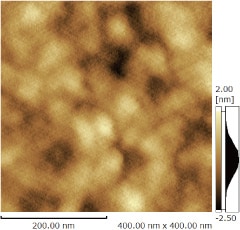

Mapping the Elastic Modulus of Styrene-Butadiene Rubber

Surface Shape

Elastic Modulus

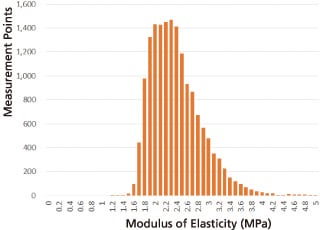

Histogram of Elastic Modulus

Mapping the elastic modulus of styrene-butadiene rubber (after Soxhlet extraction)

allowed evaluating the uniformity of the material based on the elastic modulus histogram.

(Sample source: Professor Nakajima, Department of Chemical Science and Engineering, Tokyo Institute of Technology)

Visualization of Nano-Scale Elastic Modulus and Adsorption

The elastic modulus can be evaluated quantitatively by applying a theoretical model for calculating elastic modulus to the force curve obtained by measuring the micro-forces acting between the probe and sample. The force distribution can also be visualized in the vertical direction for nano-scale three-dimensional mechanical analysis.

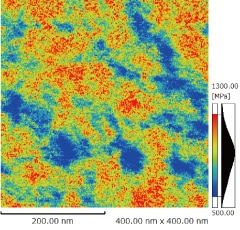

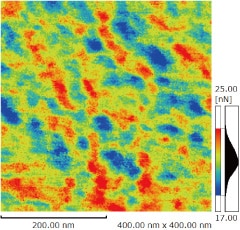

Mapping the Physical Properties of Polymer Films

Surface Shape

Elastic Modulus

Adhesion

Mapping polymer film surface properties clearly showed how elastic modulus and adhesive forces were distributed in patches several tens of nanometers in size.

(Sample source: MORESCO Corporation)

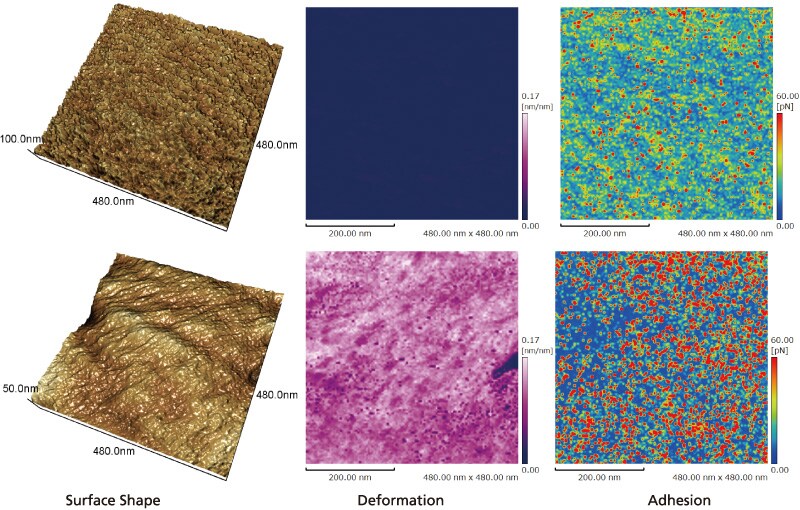

Mechanical Property Comparison of Different Samples

Measuring the Shape of Contact Lenses

Physical properties were mapped for two different types of contact lenses, made by different manufacturers, measured in an artificial tear solution. The map shows differences in surface properties of the two samples. The upper contact lens deforms more easily and exhibits uniform adsorption forces.