Introduction of Preparative Systems According to Purpose

Shimadzu strives to improve the purity, speed, and cost efficiency of preparative HPLC. Shimadzu has a worldwide sales record of over 2000 preparative HPLC units, which are being used across a range of scales and applications.

This page introduces the features of each system, to allow the customer to select the appropriate preparative system for the target fraction volume and sample type.

Large-Scale Preparative System

Large-Scale Preparative System (20AP type)

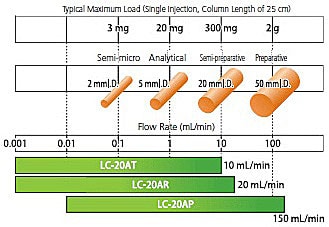

The large-scale preparative system employs an LC-20AP solvent delivery unit. This is a powerful unit offering a maximum flow rate of 150 mL/min that is suitable for automated continuous fractioning with a 20 to 50 mm I.D. column. It can also be used to investigate separation conditions and load conditions and to test the purity of liquid fractions using an analytical column (1 mL/min).

The system can be configured using a variety of options, including five sample injectors, three recycle valves, and two fraction collectors.

General-Purpose Semi-Preparative System

Semi-Preparative System (20AR type)

A system using LC-20AR supports columns from analytical columns to 20 mm I.D. semi-preparative columns and a system using LC-20AT supports columns from semi-micro analytical columns to 10 mm I.D. semi-preparative columns. Systems can be configured to suit their purpose, from simple systems with manual injection and isocratic separation to automated systems with Autosampler injection and gradient elution.

LCMS/ELSD Preparative System

If the target compound does not absorb light or if the impurities in the sample solution do not absorb light, the preparative purification efficiency can be enhanced by also using a detector not based on the principle of light absorption, such as an ELSD (Evaporative Light Scattering Detector) or MS (Mass Spectrometer). In particular, fractioning using an MS trigger can exploit the high selectivity of LCMS to achieve high purity of the target component from samples that contain many impurity components.

Analytical/Preparative Automatic Switching System

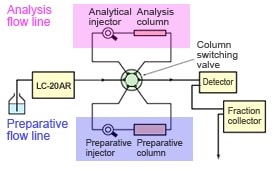

Analytical/Preparative Automatic Switching System Flow Diagram

The Analytical/Preparative Automatic Switching System permits smooth investigation of the fractioning conditions at both the analysis and preparative scales. Simply operating a flow-line switching valve makes it easy to switch between the analysis and preparative scales. Using a single system to handle all processes from investigating separation conditions and sample loads with a conventional column to scaling-up reduces the consumption of mobile phase solvent. After fractioning, this system allows smooth and efficient switching to the analytical mode.

High-Performance Preparative Recycle System

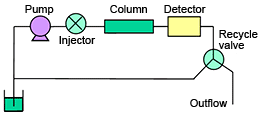

Closed-Loop Recycle Flow Diagram

The recycle separation method achieves an effect equivalent to increasing the column length by repeatedly introducing into the same column the eluate band containing the target component that eluted from the separation column.

High-Performance Semi-Preparative Recycle System (20AR type)

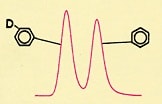

This preparative recycle system using a 20AR or 8A solvent delivery unit (max. flowrate: 20 mL/min with 20AR, 150 mL/min with 8A) incorporates a kit to minimize the internal volume and permit highly effective recycle separation (closed-loop recycle separation). Combining this system with the appropriate column can achieve a theoretical plate number greater than 1 million. This permits separation of benzene and mono-deuteriated benzene substitute, which have only extremely small differences in properties (see diagram below).

Also, if the elution volume until the peak appears is 35 mL or more, recycle separation can be performed with an analysis size column (see diagram below).

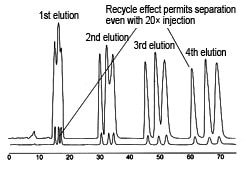

Recycle separation is perceived as a time-consuming technique. However, in separation of proximate components, the fractioning rate per unit time can be increased in some cases by using recycle separation with the injection of a large amount of sample (see diagram below).

Separation of Benzene and Mono-Deuteriated Benzene Substitute Column: STR ODS-II (250 x 20 mm I.D.) x 2

Increased Fractioning Rate Using Recycle Separation with Analytical ODS Column Column: STR ODS-II (150 x 6 mm I.D.) Flowrate: 2 mL/min, sec-/iso-/n-butylbenzene

Open Solution — Supports Compound Check and Purification

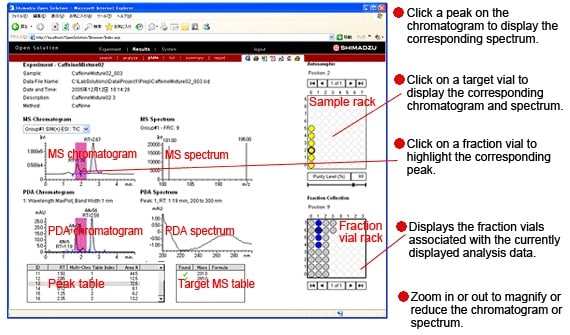

Preparative systems are often used for the synthesis checks and purification of compounds. However, the large number of samples handled results in fractioning to a huge number of vials, which makes it difficult to determine which peak was fractioned to which vial. Therefore, error-free sample tracking is extremely important for the samples supplied for fractionation, their respective chromatograms and peaks and the associated vials (target component fractions).

Open Solution displays the mutual relationship between the vial rack diagram, the fractionation results, and the fraction vials. Click on a vial to immediately check the relationship between the chromatogram, fraction vial, and spectra.

Open Solution Fractioning Results Check Window