Increased Accuracy for Low-Pressure Mixing Gradients

HPLC gradient elution systems can be categorized according to their configuration as high-pressure gradient elution systems or low-pressure gradient elution systems. This page introduces measures to make accurate and stable concentration settings for a low-pressure gradient elution system, based on Shimadzu's new LC-2010 Series High-Performance Liquid Chromatographs.

(1) Driving the Solenoid (Mobile Phase Mixing Valve)

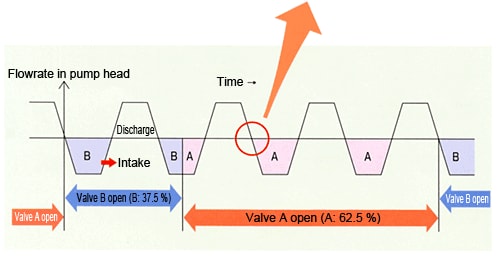

To reduce dead volume and flow pulsation, the LC-2010 Series uses a serial double-plunger pump, incorporating a primary pump head with a 10 µL plunger capacity. In a low-pressure gradient elution system, a solenoid valve switches in synchronization with the pump intake stroke to mix multiple mobile phases. The small-capacity plunger pump requires the solenoid valve to switch very frequently and can be considered disadvantageous to making accurate concentration settings.

However, LC-2010 solves this problem by assigning the 100 % concentration to four intake cycles, as shown in Fig. 1. Fig. 1 shows the flowrate fluctuations in the pump head and the solenoid valve operation timing when the concentration is set to B: 37.5 % and A: 62.5 %.

(2) Correcting Effects Due to Mobile Phase Compressibility

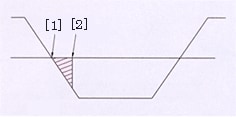

Fig. 2 shows a magnified view of the position (in Fig. 1) where the pump switches from discharge to intake. At position [1] in Fig. 2, the plunger starts to switch from advancing to retracting. At this time, the high discharge pressure is maintained inside the pump head. As the plunger retracts, the compressed mobile phase expands inside the pump head. After the pressure returns to atmospheric pressure, the mobile phase starts to flow into the pump head (position [2] in Fig. 2).

No mobile phase intake occurs in the hatched area of Fig. 2. As the pressure increases, this area gets larger and the concentration error increases. To reduce the concentration error, the solenoid valve operation timing is adjusted according to the monitored pressure values. By entering the mobile phase compressibility in the instrument (COMP parameter), the solenoid valve operation can be matched to the compressibility of the mobile phase.

(3) Correcting Errors Due to Solenoid Valve Response Delay

A time delay in the order of a few milliseconds occurs from the time of signal input until the solenoid valve operation is complete.

The solenoid valve operation is advanced by a time corresponding to this delay.

(4) Correcting Mechanical Errors

Fig. 2

Mechanical errors in the plunger drive mechanism (cams, etc.) can affect the concentration accuracy. However, the set concentration and actual concentration values are calibrated before dispatch of the LC-2010 Series.

Thanks to these measures, the LC-2010 Series achieves ±0.5 % concentration accuracy (water/acetone mixture, 0.1 to 2.0 mL/minute, 1 to 20 MPa).

Fig. 1