Automotive Engineering Exposition 2024;

Promoting Products Useful for Quality Control in the Automotive Industry

Shimadzu booth at the Automotive Engineering Exposition 2024 YOKOHAMA held in May

Shimadzu Corporation and Shimadzu Techno-Research, Inc. exhibited at the Automotive Engineering Exposition 2024 held in May and July*. This article looks at the Shimadzu booth and provides an overview of our exhibit.

- *The “YOKOHAMA” exposition was held from May 22 to 24 at PACIFICO Yokohama, and the “NAGOYA” exposition from July 17 to 19 at Aichi Sky Expo.

Automotive Engineering Exposition, the Largest Exhibition of Automotive Technology in Japan

The Automotive Engineering Exposition is the largest exhibition of automotive technology and parts in Japan, and is held once a year in Yokohama and Nagoya. This year, 590 companies and 303 companies with the latest car-related technologies from a wide range of fields, not just car manufacturers, exhibited respectively in Yokohama and Nagoya. The total number of visitors over the 6 days exceeded 100,000.

A Lineup of Products Useful for Quality Control at the Shimadzu Booth

On display at the Shimadzu booth were actual models of instruments that are useful for strength tests and durability tests of parts from the automotive industry, and for nondestructive internal defect inspections, and screening inspections for regulated elements.

| Product Name | Model | Features |

|---|---|---|

XSeeker 8000 XSeeker 8000 |

Bench-Top X-Ray CT System |

The X-ray CT system is equipped with a high-output X-ray generator and a high-resolution flat panel detector. Although it is a compact bench-top CT system, it has a high X-ray output of 160 kV, enabling nondestructive observations of the internal structure and defects in thick plastic parts, as well as aluminum die cast parts and other metal parts. This model is simple to operate and does not require high-level expertise, and it provides high throughput with scans as quick as 12 seconds, so it can be used at any site requiring inspections at short times. |

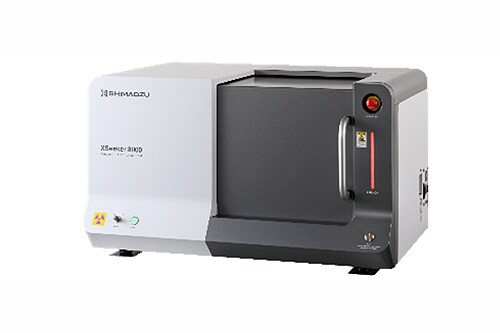

EDX-7200 EDX-7200 |

Energy Dispersive X-Ray Fluorescence Spectrometer |

This instrument can perform nondestructive analysis of samples with a variety of forms including solids, powders, and liquids. In addition to providing high speeds, high sensitivity, and high accuracy, usability has been pursued to ensure that it can be operated by anyone to obtain stable data. It can be used in various fields for acceptance inspections, screening for toxic elements, contaminant analysis, and component analysis. |

AGX-V2 Autograph AGX-V2 Autograph |

Precision Universal Testing Machine |

This instrument can measure the strength of materials, as well as changes in strength when a force is applied. It is equipped with a voice control unit, a world’s first, to improve operability, safety, and testing efficiency. In addition to the development of materials such as carbon fiber reinforced plastic (CFRP) and metals, this instrument is used for various tests, inspections, and evaluations aimed at the realization of even higher performance machining methods at production sites. This contributes to transportation equipment related research and development and quality control. |

EMT Series EMT Series |

Electromagnetic Fatigue and Endurance Testing System |

This instrument assesses the fatigue strength and endurance of specimens by continuously applying loads with a variety of waveforms, frequencies, and sizes. It is used for the evaluation of vibration damping characteristics that limit vibrations to improve automotive comfort, and for evaluating the durability of resins and rubber materials, automotive parts, electronic parts, and new materials. |

In addition to exhibiting actual instruments, Blue Impact, a high power, high intensity blue laser light source for copper machining was introduced, as were applications related to the multifaceted evaluation of lithium-ion batteries, a focus of interest in recent years; as well as the nondestructive analysis of automotive electrical parts for the advanced driving assistance system (ADAS); evaluative techniques supporting the development of hydrogen storage and transport parts; and evaluations of the deterioration of plastics.

Shimadzu Techno-Research, Inc. established a contract analysis corner, and mainly introduced applications related to lithium-ion batteries and materials evaluations.

Comment from the Person in Charge of the Shimadzu Booth

At the Shimadzu booth, we exhibited the latest applications and many actual instruments related to the evaluation of automotive parts and materials to contribute to solving the analytical and measurement problems facing our customers. Our exhibition received a great deal of feedback. We are truly thankful that so many people visited the Shimadzu booth in Yokohama and Nagoya during this year’s Automotive Engineering Exposition.

Page Title and URL Copied.

Page Title and URL Copied.