Analysis of Microplastics in Environmental Water Using Microplastic Automatic Preparation Device MAP-100 and FTIR

This page introduces an example of analysis of microplastics in environmental surface water using a microplastic automatic preparation device MAP-100 and FTIR. Samples collected from a river were pretreated using the MAP-100. Based on Ministry of the Environment guidelines, in this experiment, digestion was conducted for 3 days, followed by separation for 3 hours. Fig. 1 shows the condition of the sample before preparation, during digestion(1 day after the start of treatment), and after preparation. From Fig. 1c, it can be understood that environmental contaminants could be removed cleanly by preparation with the MAP-100.

Fig. 1 Condition of Sample Before/After Preparation and during Digestion

a: Before Treatment, b: During Digestion (1 Day After Start of Treatment), c: After Treatment

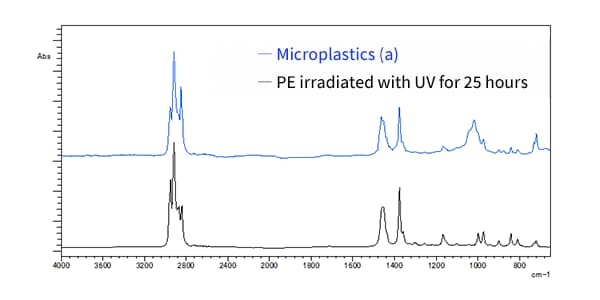

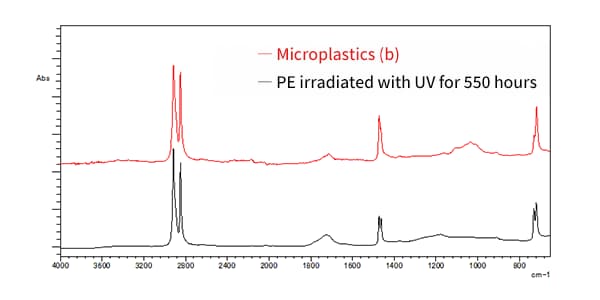

A material analysis of the microplastics obtained by preparation using the MAP-100 was carried out using the Fourier transform infrared spectrophotometer (FTIR). In this experiment, we used a plastic analysis system, Plastic Analyzer, which is effective in analyses of degraded microplastics. Fig.2 shows the appearance of two measured microplastics, and Fig.3 and Fig.4 show the measurement results of the obtained infrared spectra and the search results using the UV-Damaged Plastic Library, which is an original Shimadzu database.

Fig. 2 Appearance of Microplastics (a) and (b)

Fig. 3 Infrared Spectrum and Search Results for Microplastic (a)

Fig. 4 Infrared Spectrum and Search Results for Microplastic (b)

From Fig. 3, a hit for polypropylene (PP) irradiated with UV for 25 hours was obtained for microplastic (a), and from Fig. 4, a hit for polyethylene (PE) irradiated with UV for 550 hours was obtained for microplastic(b). The respective hit rates showed extremely high scores of 876 points for (a) and 904 points for (b). It is thought that these excellent scores were obtained because the infrared spectra of the simple plastic could be acquired by removing environmental contaminants with the MAP-100.