MUP-3100 - Features

NEWFully Automated Sample Preparation Module for Glycan Analysis

-

Precisely Automated Protocols Eliminate Human Error

-

Simply Place the Sample and Reagents in the Instrument to Automatically Implement Pretreatment

-

Automatic Confirmation of Consumables Positioning Supports Stable Operations

-

Antibody N-glycan analysis kit “Auto-EZGlycoTM mAb-N Kit for SHIMADZU”

-

Quality Control Support Functions

-

Processes 24 Culture Supernatant Samples Reliably in 6 Hours

Precisely Automated Protocols Eliminate Human Error

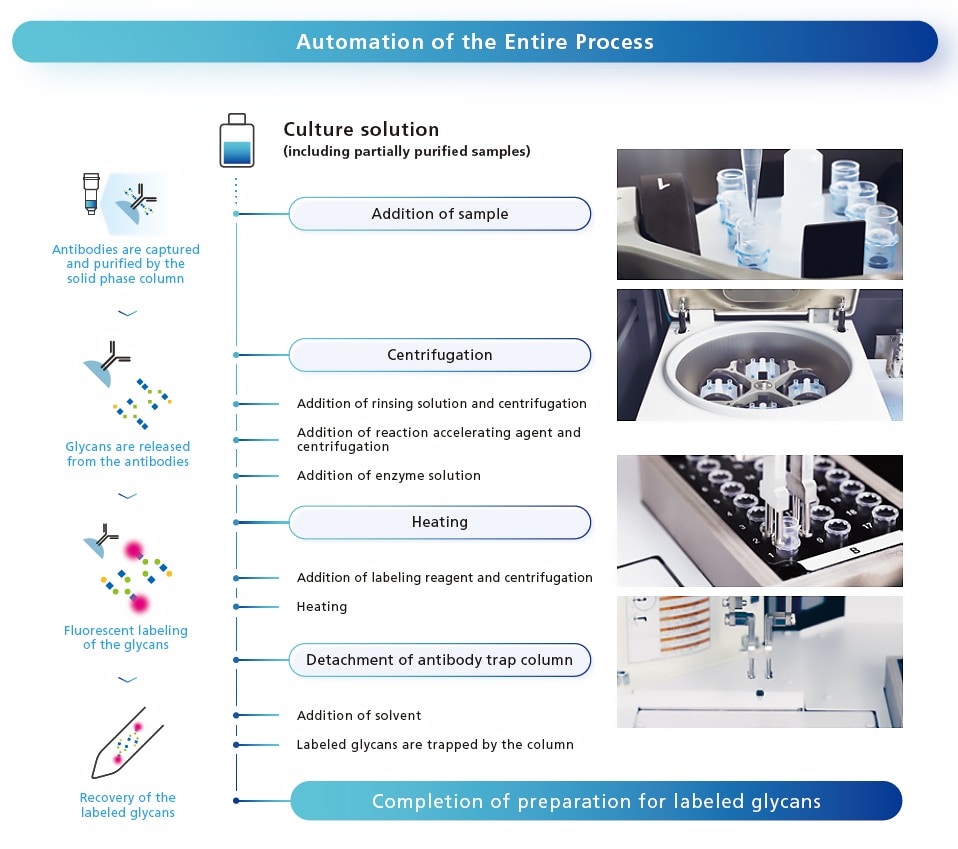

Pretreatment is required for LC analysis of profiles for antibody-derived glycans, including purification of the antibodies, glycan cut-out, and fluorescent labeling. The MUP-3100 Fully Automated Sample Preparation Module for Glycan Analysis is equipped with functions to perform dispensing, the addition of reagents, heating, centrifugation, solid phase column extraction, and sample delivery, thereby automating the entire pretreatment sequence.

Pretreatment of antibody-derived glycans in culture supernatants involves repeated operations including dispensing, the addition of reagents, centrifugation, and heating. With solid phase column extraction using an antibody trap carrier, rinsing must be performed multiple times, which is labor intensive. The MUP-3100 reliably implements pretreatment using the Auto-EZGlyco™ mAb-N Kit for SHIMADZU protocol. This eliminates human errors, such as forgetting to add the reagent, taking the wrong sample, or omitting a process.

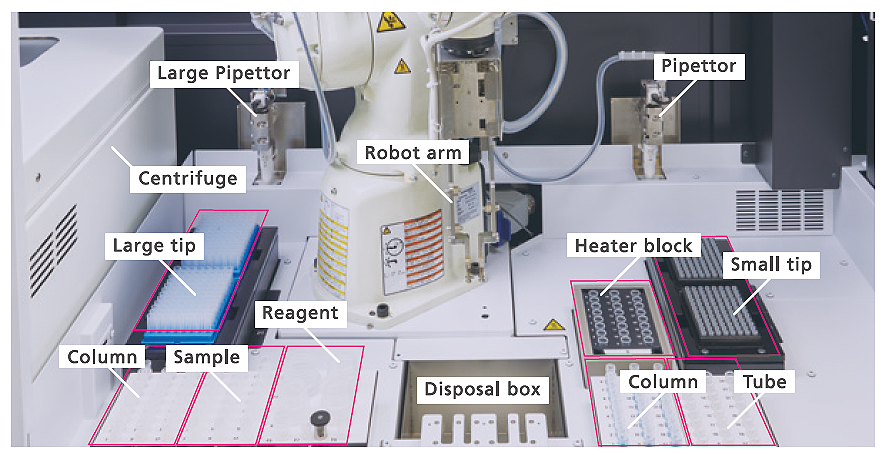

Simply Place the Sample and Reagents in the Instrument to Automatically Implement Pretreatment

Simply place the prepared reagent and the culture supernatants or other samples into the prescribed place for the instrument and select pretreatment to implement the process automatically, quickly and accurately. The MUP-3100 allows for setting a maximum of 24 samples at one time and enables processing twice a day. The MUP-3100 not only lessens the burden on the analyst, but also enables pretreatment at night or on holidays, thereby accelerating the workflow.

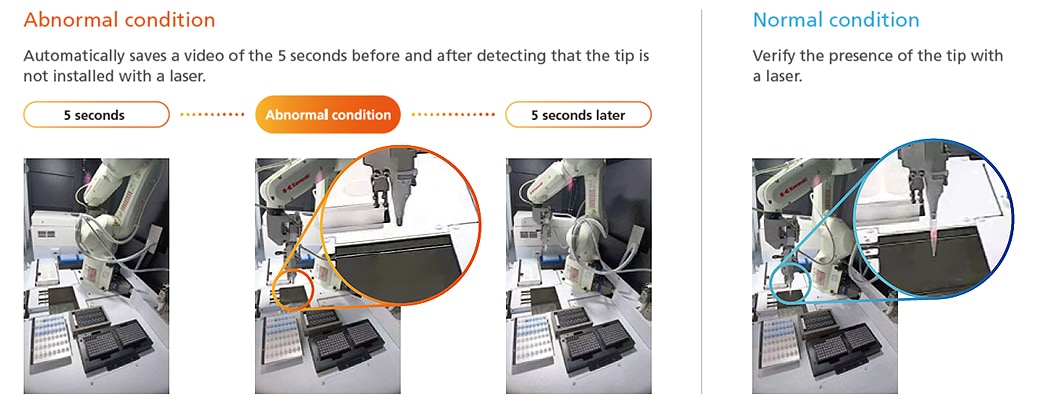

Automatic Confirmation of Consumables Positioning Supports Stable Operations

With the MUP-3100, mistakes are prevented by checking the sample and necessary reagents positioning via image processing prior to automated operations. The automated protocol will be paused if the sample, reagent, or consumables are missing. Even during automated operations, pipette tip attachment/detachment and the column grip are monitored by sensors, preventing malfunctions.

Antibody N-glycan analysis kit “Auto-EZGlycoTM mAb-N Kit for SHIMADZU”

This is capable of everything from purifying antibodies from unpurified samples (e.g. cell culture solution) and other partially purified samples, to glycan cut-out, fluorescent labeling of glycans and glycan purification. The kit also includes necessary reagents such as a ta glycan release enzyme and a glycan fluorescent labeling reagent.

Refer to Sumitomo Bakelite Co., Ltd.

Quality Control Support Functions

The control software of the MUP-3100 automatically generates pretreatment results reports and stores them in the database along with pretreatment conditions. The MUP-3100 continuously monitors its operating performance, and if the device detects an error, its internal camera automatically creates a video of the 5 seconds before and after the occurrence, which is then saved along with error logs. This assists in identifying the root cause of errors and minimizing downtime.

Processes 24 Culture Supernatant Samples Reliably in 6 Hours

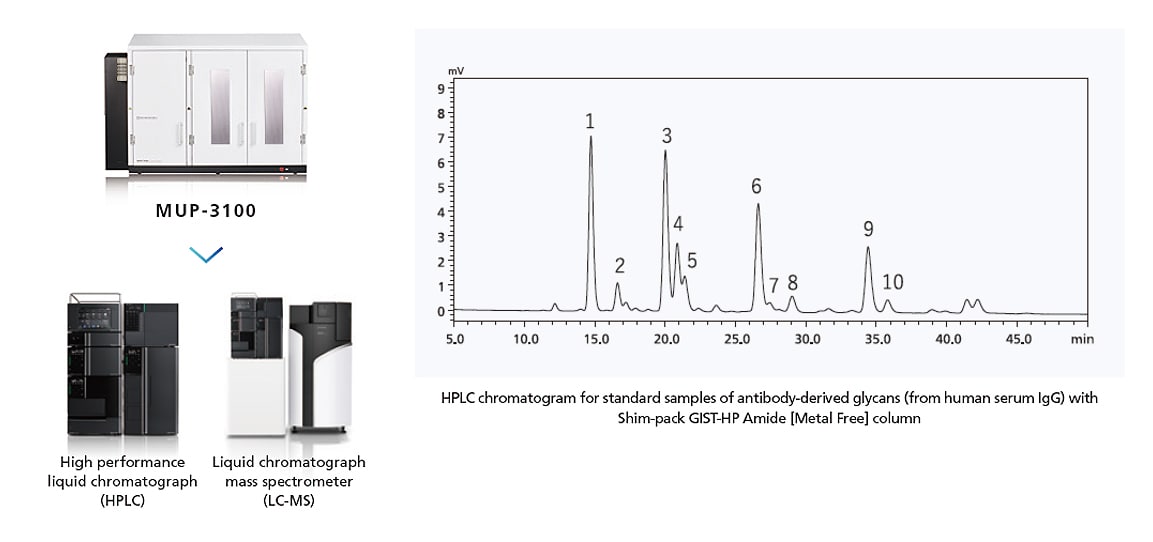

Conventional methods require complex operations to cut out glycans from antibody samples in the culture supernatant. The traditional method requires more than two days for preprocessing. When using the MUP-3100 and the antibody N-glycan analysis kit in combination, however, 24 samples can be preprocessed in six hours. Glycan profiling, including the type and quantity of glycans, can be performed by analysis of 2-AB labeled glycans using an HPLC fluorescence detector. The Shim-pack GIST-HP Amide [Metal Free] column is effective for separating out impurities and glycans contained in antibody preparations and culture supernatants.

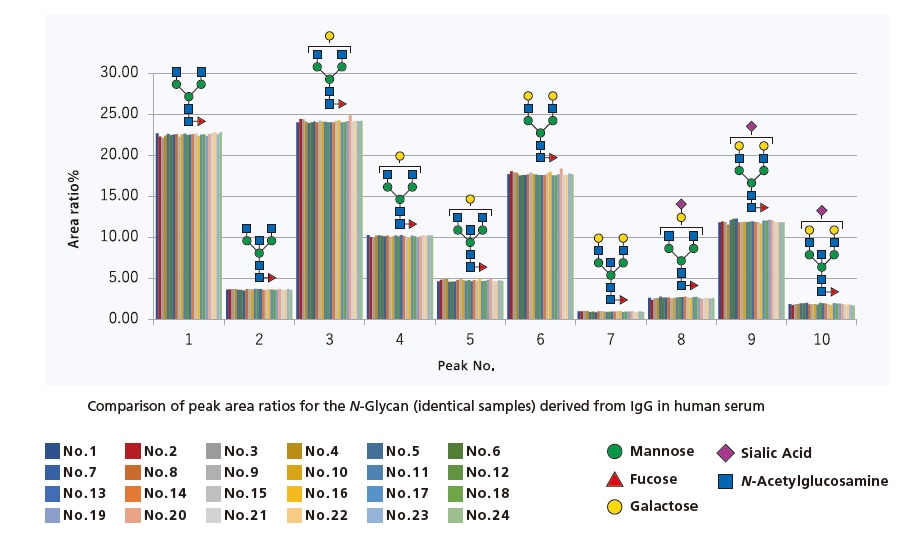

The MUP-3100 can process 24 samples at a time. Even with simultaneous processing of other samples, the area ratio of each peak remains stable regardless of peak intensity, yielding data equivalent to that obtained when using the kit manually.

Auto-EZGlyco is a trademark of SUMITOMO BAKELITE CO., LTD. and/or its affiliates.