Jetanizer - Features

A Methanizer in an FID Jet for Gas Chromatography

High Performance

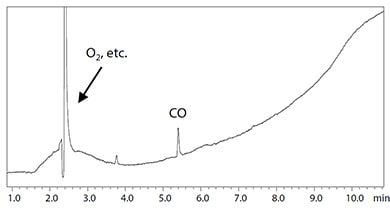

Low-level detection of CO and CO2 is important in catalysis, hydrogen (H2) purity analysis, dissolved gas analysis (DGA), greenhouse gas (GHG) analysis, transformer oil gas analysis (TOGA), ethylene/propylene monomers, safe entry analysis, and more. Conventionally, large nickel-catalyst-filled tube methanizers are used; however, they are prone to frequent failures and they are difficult to operate and maintain. Shimadzu’s Jetanizer solves these challenges by incorporating state-of-the-art catalysts into an FID jet. Moreover, the Jetanizer enables low level <1 ppm formaldehyde analysis by GC avoiding the pitfalls of HPLC analysis of formaldehyde.

List of official methods/applications for which the Jetanizer could be used

| Official Methods / Applications | Analysis Target |

|---|---|

| ISO 14687-2019 | Impurities in hydrogen (H2) |

| - | Greenhouse gas (GHG) analysis |

| ASTM D3612-02 (2017) | Transformer oil gas analysis (TOGAS) /Dissolve gas analysis (DGA) |

| ASTM D6159-17 | Impurities in ethylene |

Key Benefits over a Conventional Methanizer

| Jetanizer | Conventional methanizer | |

|---|---|---|

| Installation point |

FID nozzle |

Next to GC |

| AUX power supply |

Not required |

Mandatory |

| Catalyst |

Ni free |

Ni |

| Durability against O2 |

✓ |

× |

| Additional H2 supply |

Not required |

Mandatory |

More straightforward and highly sensitivity

- Ability to be used with formaldehyde

- Higher catalytic activity = larger linear dynamic range

- No toxic metals: The Jetanizer does not contain nickel catalysts

Cost, time, space saving

- Lower up-front cost

- No extra plumbing: minimize fittings and leaks

- No extra heater or controller: utilizes heat from FID

- FAST installation: Less than 5 minutes

- Frees up space on the GC