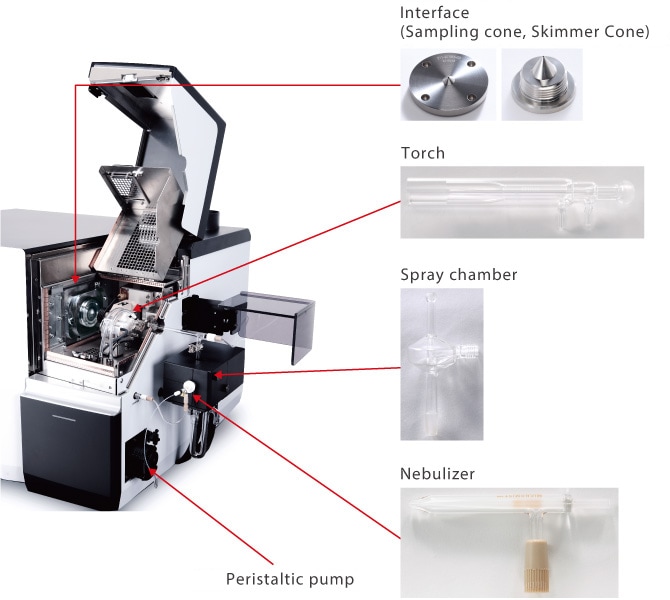

Atmospheric Pressure Part of ICP-MS System Components

Basics of Inductively Coupled Plasma Mass Spectrometry

1. Sample Introduction and Ionization

In this section, we will discuss the ICP-MS sample introduction system. The components are shown below. The peristaltic pump introduces the sample to the system and the nebulizer turns the sample solution into a fine mist. The spray chamber then separates the finest mist, which is fed into the plasma. The extremely high-temperature plasma ionizes the elements in the sample, which then pass through the interface and enter the mass spectrometer.

The condition of the sample introduction system has a strong impact on the sensitivity and accuracy of ICP-MS analysis, particularly when measuring sample elements at very low levels. This is due to a “memory effect” that can occur when elements at high concentrations in the previous sample are retained in the sample introduction system and “carried over” in subsequent analyses run. To minimize this, it is necessary to set appropriate cleaning conditions for the sample introduction system and perform maintenance as appropriate.

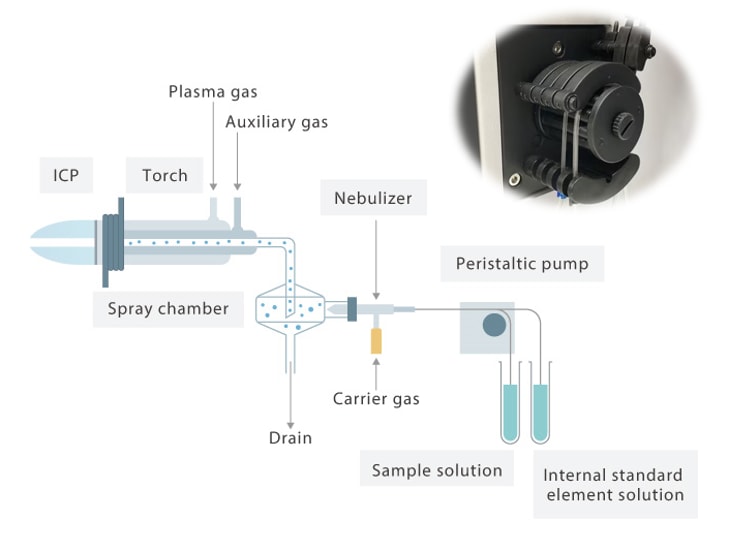

2. Peristaltic Pump

The peristaltic pump helps deliver a given volume of sample to the nebulizer. Sample can be carried into the nebulizer by the carrier gas, but the peristaltic pump allows an even and steady flow of sample to be introduced to the nebulizer. The peristaltic pump can rotate at a high speed to deliver liquid quickly for sample introduction and post-analysis cleaning. The peristaltic pump can accommodate multiple tubes and can be used to supply both the sample solution and the internal standard element solution when performing quantitative analysis with internal standard-based correction. Before reaching the nebulizer, the solutions can be mixed to a specific ratio based on the respective inner diameters of the tubes.

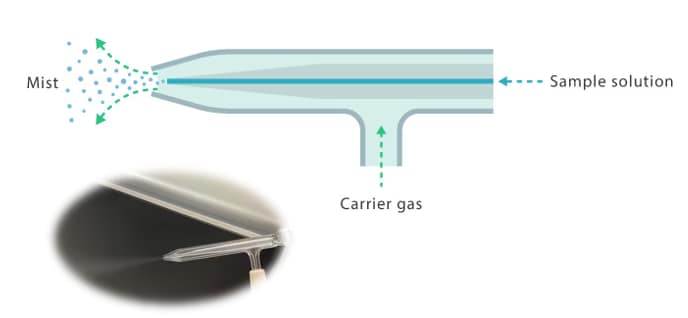

3. Nebulizer

The nebulizer is responsible for turning the sample solution into a fine mist. Concentric nebulizers are typically used for sample introduction in ICP-MS. In a concentric nebulizer, the sample delivery tube sits inside the carrier gas delivery tube. The diameter of the sample and carrier gas tubes narrow at the nebulizer tip and allow flow due to the Venturi effect. Sample solution that enters the nebulizer is torn into droplets by the pressure of the carrier gas and is sprayed from the nebulizer as a fine mist. The particle components larger than the diameter of the sample delivery tube or nebulizer tip cause clogging and prevent the formation of a good spray. Therefore, suspended solids must be removed with filter paper, etc. before introducing the sample solution.

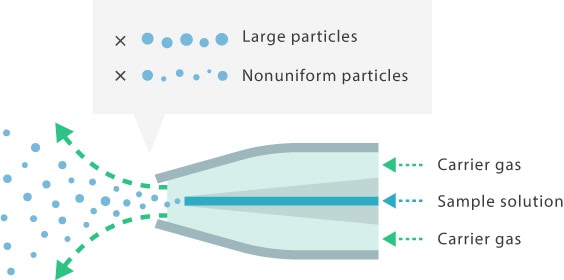

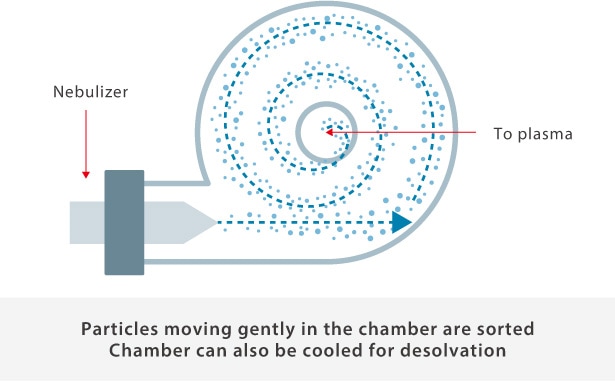

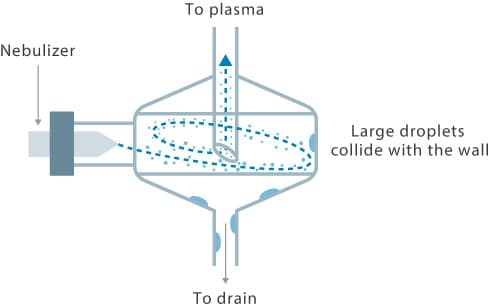

4. Spray Chamber

The mist created by the nebulizer contains large aerosol particles. The spray chamber removes these larger droplets from the nebulizer to ensure stable analysis. When using a twister cyclonic spray chamber, the nebulizer is positioned tangential to the chamber and the mist sprayed by the nebulizer is carried through the spray chamber in a circular motion. When the spray is passed through the spray chamber, large aerosol particles collide with the spray chamber wall and are discharged to the drain. As a result, only small aerosol particles are carried to the plasma by the carrier gas. Cooling the spray chamber can significantly aid in this process. The sample desolvation effect can be used to reduces plasma temperature drop and reduces interference from solvents.

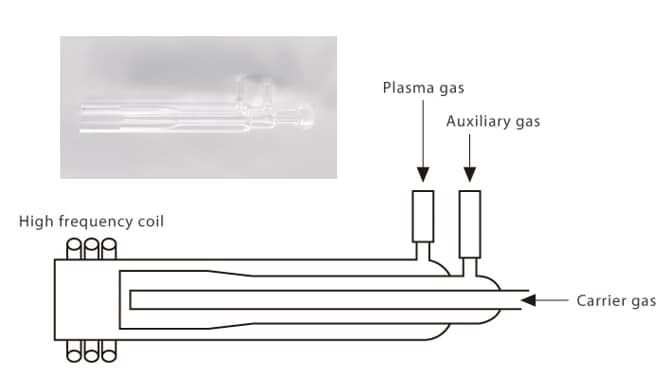

5. Torch

The torch for aqueous sample solutions is made of quartz and has a three-tiered concentric tube design. The plasma gas is introduced into the outermost tube and creates a cooling and insulating sheath around the plasma. The auxiliary gas is fed to the center tube. It serves to slightly float the plasma and protect the intermediate quartz tube. The innermost tube is referred to as the injector and carries the sample and carrier gas to the base of the plasma. Different torches are designed for different sample solutions. A torch with parts made of alumina is used for sample solutions that contain hydrofluoric acid, whereas a four-tiered concentric tube torch with an additional Ar/O2 gas stream for solvent combustion is used in the analysis of organic solvents.

The end of the torch can become fouled due to metals and organic materials in the sample, in which case the deposits must be removed by acid or heat treatment. The end of the torch can also turn white (devitrification) or develop cracks and chips with extended use and must be replaced when these types of changes cause a deterioration in measurement accuracy.

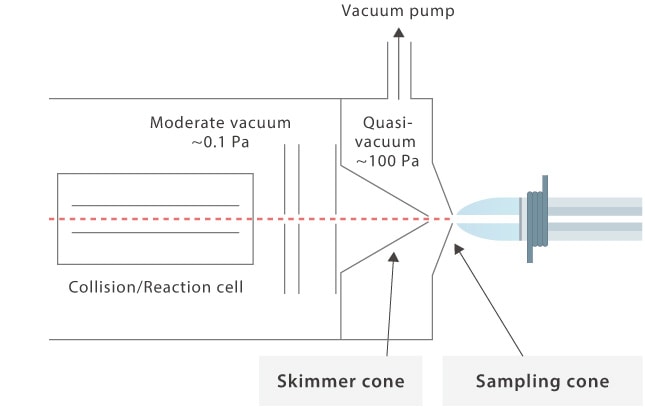

6. Interface (Sampling Cone and Skimmer Cone)

The ions are generated in plasma at atmospheric pressure and then drawn into a vacuum region at the interface where the mass separation unit is located. The interface consists of a sampling cone and a skimmer cone. Between the two cones is an area maintained at a low vacuum of around 100 Pa by a rotary vacuum pump. The sampling cone has an aperture of approx. 1 mm at its tip, while the skimmer cone has an aperture of approx. 0.4 mm at its tip. These tips are very delicate, so be very careful when cleaning sampling and skimmer cones. Both cones are water-cooled because they come into direct contact with the extremely high-temperature plasma. Interface cones can be made of nickel, copper, or platinum. The material choice is dictated by the application. When the concentration of the analyte is very low and quantitative measurements are impacted by the background signal from the cone material itself, a different cone material is selected. Platinum cones are extremely durable and used to introduce samples that contain highly corrosive substances such as hydrofluoric acids.

Skimmer cone / Sampling cone