Inspection Case

MIV-X

MAIVIS Ultrasonic Optical Flaw Detector

Make It Visible!

Visualizing Cracks, Voids, Delamination, and Other Hidden Defects Normally Impossible to Check Visually

Anyone Can Quickly and Easily Perform a

Visual Surface Inspection

Thanks to Shimadzu’s proprietary light imagining technique,

which combines an ultrasonic oscillator with a stroboscope,

defects near the surface of a material, including peeling of the bonding and adhesive surfaces of heterogeneous materials, as well as paint, thermal sprays, and coatings can be inspected easily and non-destructively.

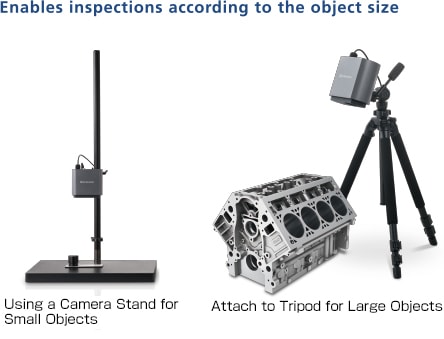

- Simply attach the ultrasonic oscillator to the sample, and position the camera above the inspection surface.

- The propagation of the ultrasound is quickly displayed, and flaws are easily identified from the video.

- The easy-to-operate software is enhanced with functions to mark the flaws and measure the size easily.

- The lineup includes an optional optical zoom set, which can detect smaller flaws.

Utilized in Various Industries

-

Ultrasonic optical flaw detection enables the visualization of internal flaws (at a depth of about 1 mm) that are hard to find using conventional ultrasonic testing. It can easily detect flaws in joints and bonding surfaces in research and development processes involving multi-materials, which are created by combining different materials to increase strength and reduce weight.

Inspection Result Screen

Features

-

With ultrasonic optical flaw detection technology, the sample is encouraged the displacement of the surface is detected optically, and the propagation of the ultrasonic wave on the surface is observed.

-

The MIV-X Ultrasonic Optical Flaw Detector assists with regions where ultrasonic testing (UT) is difficult. Leave the non-destructive inspection of surfaces and near surfaces to MIV-X!

-

The instrument is equipped with a function to digitally remove noise in the window showing the propagation of the ultrasound, simplifying flaw identification.

-

The instrument is equipped with a user interface that simplifies operations, such as displaying a scale (ruler) on acquired images of cracks and peeling and measuring the distance between two selected points.

-

Decreases the minimum detection size by a factor of approximately two (MIV-X standard: From approximately 1 mm dia. to 0.5 mm dia.)

Laser optical axis adjustment is also possible, improving irradiation uniformity

Videos

-

MIV-X: Ultrasonic Optical Flaw Detector

-

MIV-X: Inspection Procedure in 4 Steps

-

Multifaceted Evaluation of High-Tensile Strength Joints b/w Dissimilar GA Steel & Al Sheet Materials

This video shows examples and effectiveness of multifaceted evaluation of joint of dissimilar materials with ultrasonic optical defect detector, X-ray CT system, electron probe microanalyzer (EPMA), and precision universal testing machine.

Downloads

Download the latest brochure.

News / Events

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.

-

New Autograph AGX-V2 Series Precision Universal Testing Machines

The World’s First Testing Machines Equipped with a Voice Operation Device

-

Cellulose nanofibers

Given that cellulose nanofibers(CNFs)offer attractive physical characteristics, such as light weight, strength, and hardness, they not only enable materials with advanced functionality, but are expected to be used as a reinforcing material that can reduce the weight of composite materials.

-

Latest issue of Shimadzu Journal, featuring Materials Science, has come out.

This issue focuses on Materials Science particularly on lithium-ion batteries (LiBs). It starts with two customer interviews in which users discuss their relationship with Shimadzu.