From Clocks to Aircraft, Gears Are Used to Control the Speed and Torque of Power Sources and Are Essential to Societal Progress

Series: Shimadzu's Heritage

Gears are machine elements that convert and transmit torque from motors and engines to industrial equipment at useful rotational speeds. Gear wheels are an essential part of almost every piece of machinery that runs on motive power, and societal progress is underpinned by the engineering found in every single gear wheel.

Wielding Power through an Assembly of Gears

Gears have long been an essential component of industry. A single gear is no more than a wheel with notched teeth, but by coupling gears together and combining them with components designed to interface with the same notched teeth, they are capable of controlling and transmitting torque, direction of power, and speed of movement.

To illustrate this, if a 100-tooth gear turns a 50-tooth gear, the 50-tooth gear rotates twice for every single rotation by the 100-tooth gear. This doubles the amount of rotary motion. Alternatively, rotary motion is halved when a 50-tooth gear turns a 100-tooth gear, as a single rotation of the 50-tooth gear produces a half rotation of the 100-tooth gear. However, the power applied to the 50-tooth gear does not halve accordingly; instead, the 100-tooth gear turns with twice the power (torque) of the 50-tooth gear. This is termed a reduction gear and is used to supply high torques on-demand in a variety of situations. Reduction gears can be considered the main advantage afforded by gears.

The most familiar application of reduction gears is in a motor vehicle transmission, which generates high torques by slowing down the engine speed from several thousand revolutions per second and thereby allows vehicles that weigh over a ton to start smoothly from a standstill.

Gears come in all sizes. Some of the smallest gears, under 1-mm in size, can be found in wristwatches whereas some of the biggest, measuring several meters in size, are used in ocean vessels and wind turbines. Gears that control the speed and torque delivered by a power source are particularly important in industrial machinery. The wheel is called the greatest invention of humankind, but the invention of gears may be considered of equivalent significance.

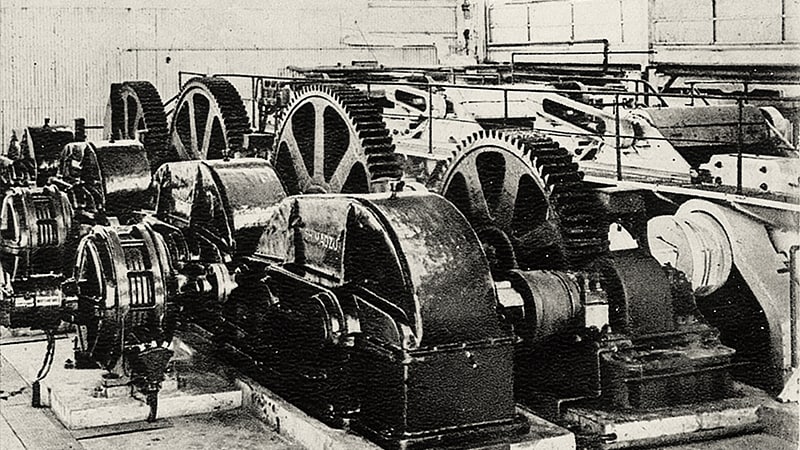

A Shimadzu reduction gear “gear coupling” installed in a hydraulic press in a sugar factory.

Gears are used in all manufacturing plants to control the speed and power of industrial machinery.

Aircraft Gear Manufacturing Requires an Array of Artisan Skills

An aircraft is probably one of the most demanding industrial products in terms of technical performance. Raising a lump of metal into the air against the pull of gravity requires reducing the weight of every single component. However, these components must also be durable, as device malfunction or component failure can lead directly to an accident.

Gears are not exempt from this threat. Aircraft carry a variety of large and small gearboxes with approximately one thousand gear wheels distributing the high-speed rotational movement generated by aircraft engines to mechanisms located throughout the airframe. Each of these gears has been engineered to improve its toughness and weight.

Gear weight can be reduced by creating smaller and thinner gears, but the thinner the gear, the less durable it becomes. Exposing parts under-engineered for strength to excessive force can cause deformation. Contact surfaces must be hard enough to resist deformation, but manufacturing an entire gear wheel from hard material risks brittleness and potential gear tooth fracture.

This problem is overcome using a treatment technology called carburizing, which hardens the contact surfaces of meshing gear teeth by adding carbon to the surface layer via a quenching and tempering process. This otherwise retains the mechanical qualities of steel, preserving the toughness needed to absorb shock loads. Finding steel of sufficient hardness that readily absorbs carbon and making improvements to the surface hardening process are the most important challenges facing the development of gears for aircraft.

The heating and cooling performed during tempering and quenching also distort the shape of gear teeth that must be dimensionally accurate to exert forces according to design. For this reason, the shape of each tooth must be corrected by polishing them one by one after the carburizing process. The labor involved in producing gears for aircraft resembles the efforts of a skilled artisan.

Shimadzu Gears Used in Japan’s First Passenger Aircraft

In the 1910s and 1920s, Shimadzu produced reduction gear “gear couplings” for industrial machinery. At the time, motive force was transferred from power sources to machinery entirely via belt drive systems, and Shimadzu sales personnel visited customers throughout Japan explaining the excellent power transmission efficiency, superior speed conversion, and other virtues of gears. In the 1930s, Shimadzu entered the aviation industry market and produced hydraulic equipment and carburetors.

Shimadzu combined the experience and knowledge gained in these two businesses to produce gearboxes for aircraft. In 1955, the company began to manufacture equipment for a government-led aircraft project. Two years later, in 1957, Shimadzu established an Aircraft Equipment Division to properly commercialize the business, and in 1961, manufactured gearboxes for flaps (a high-lift device) on Japan’s first passenger aircraft, the YS-11.

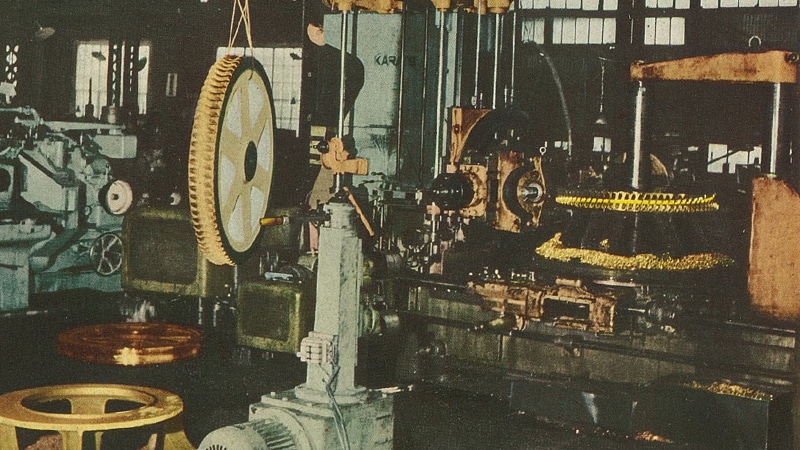

A Shimadzu gear manufacturing plant around 1960

Later, Shimadzu manufactured gearboxes for flaps on Boeing’s Jumbo Jet. This demonstrated the trust garnered by Shimadzu as one of a few companies capable of undertaking the entire gearbox production process according to customer requirements, from gearbox design to manufacturing each gear wheel to assembly of the end product.

Pursuing Evolving Demands in Technological Development for Gearboxes

Technological development in gearboxes is evolving toward increased power transmission efficiency alongside improvements in weight and toughness. Gear wheels in gearboxes are constantly sliding and rolling against one other. This sliding produces frictional losses that reduce transmitted power. Once assembled, a gearbox designed to transmit a theoretical power of 2 will only transmit a power of 1.7. For this reason, the power needed to operate flaps and other aircraft mechanisms is output by increasing the input power into the gearbox.

With a growing demand to reduce energy consumption in the aircraft industry, Shimadzu has proposed an alternative gearbox design to aircraft manufacturers that modifies the gear tooth profile to minimize power transmission losses.

The role of aircraft is likely to grow due to the expanding demand for logistical services that underpin increasing globalization and lifestyles throughout the world. Shimadzu will continue to focus its passion on the development and complex manufacture of gears that support this growing demand.

Copied

Copied