The Third Wave of Chromatography

Supercritical Fluid Chromatograph for High-Speed Simultaneous Analysis of a Wide Variety of Substances

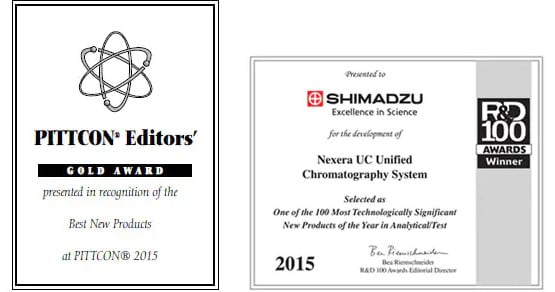

In 2015, Shimadzu's Nexera UC system was awarded the Pittcon Editors' Gold award, the highest award available, at the Pittcon Conference & Expo, the world's largest analytical instrument exhibition as well as an R&D Magazine R&D 100 award. The award from R&D magazine recognizes Shimadzu’s Nexera UC system as one of the 100 most technically significant new products of the year in the analytical and testing category.

The Nexera UC system, which is based on using supercritical fluids, has the potential for changing the standards for analysis. This article explores the background to how it was developed.

Breathtaking Analysis Speed

"So this is SFC? Very impressive!"

In the spring of 2014, the team in charge of developing applications for the supercritical fluid chromatograph (SFC) system scheduled for release in the next year were riveted to the monitor.

"Absolutely!"

Even Masami Tomita, General Manager of the LC Business Unit in the Life Science Business Department of Shimadzu Corporation's Analytical & Measuring Instruments Division, the person responsible for developing the system and who was watching the demonstration, could not take his eyes away from the data being output so quickly by the prototype system.

Chromatography is an analytical technique used to separate and identify the various components contained in substances. Gas chromatographs (GC) achieved widespread use from about 1950, and liquid chromatographs (LC) from about 1970. They have been used for a wide variety of applications, with their use differentiated based on the properties, purpose, and application of the substance being analyzed. Then in the late 2000s, supercritical fluid chromatography (SFC) started gaining attention due to the increasingly widespread use of high-speed analysis. SFC systems are able to measure a wide range of components, including components readily soluble in liquids, for which LC is well suited, and components that are readily volatilized, for which GC is well suited.

The biggest reaction came from the pharmaceutical manufacturing industry. SFC systems are able to cleanly separate substances that are difficult to separate with conventional chromatography, such as optical isomers*1, which are substances composed of identical components but that are different structurally. The teratogenic thalidomide drug scandal that occurred in the 1960s was caused by optical isomers contained in the drugs, one of which was highly toxic. The toxic isomer must always be separated and recovered, but separation by LC is time-consuming, so there was demand for a new technique. There are also many other drug ingredients that contain optical isomers that often cannot be separated without an SFC system.

*1 Optical isomers are substances made of identical components, but with two different structures that are left-right mirror reflections of each other. Due to their relatively similar chemical properties, they can be difficult to separate. Professor Ryoji Noyori received the Nobel Prize in Chemistry in 2001 for developing an effective method for selectively synthesizing specific isomers.

Unexpected Request

In the spring of 2011, Yosuke Iwata, who works as an engineer for LC instruments at Shimadzu Corporation, was caught off guard by an unexpected request from then Associate Professor Takeshi Bamba of Osaka University, who was visiting Shimadzu Corporation.

Bamba suggested that he develop an SFC system together with Shimadzu using some interesting technology that he was working on.

Associate Professor Bamba was a leader in research into SFC technology. The interesting technology he referred to is based on combining SFC and supercritical fluid extraction (SFE) technologies. SFE involves using a supercritical fluid*2 to directly extract components from solid samples and so on. Conventional methods require considerable time and skill to pretreat samples before analysis, which makes the process difficult to automate. However, the new technology would significantly simplify the process. SFE is also a good fit for SFC, which involves using the same supercritical fluids. This technology was already being used by Takashi Ando, Director at the Miyazaki Agricultural Research Institute, who was actively involved in analyzing residual pesticides and functional components in foods. However, an integrated (online) analysis system that combined SFE and SFC with a mass spectrometer (MS) for measuring component quantities still had not been developed. If an online system could be developed, it would eliminate the exposure of samples to air during transfer between the instruments. That would solve the problem of oxidation changing the components, which was the main weakness of the existing pretreatment method. Associate Professor Bamba was keen to obtain such a system. Associate Professor Masaru Yoshida at the Kobe University School of Medicine, who is involved in using trace amounts of blood to search for disease markers, was another person trying to accelerate his research using the system's unique features.

Yosuke Iwata

Yosuke IwataDeputy Manager of the Instrument Development Group, LC Business Unit

*2 Supercritical fluids are fluids in a state above the critical point (temperature and pressure limit point where a substance is able to transition back and forth between the gas and liquid states), where they exhibit both the low viscosity and high diffusivity characteristics of gases and the high solubility of liquids.

Pinch and Release

The request from Associate Professor Bamba provided a great opportunity for Shimadzu to get involved in SFC.

Development started right away but, of course, progress was not straightforward. The biggest problem was the valves used to control pressure. For SFC, even slight pressure variations in the chamber filled with supercritical fluid can affect the state of the separation. The accurate functioning of the valves that control that pressure serves as a key factor in separation analysis. The SFC system faced issues for a long time due to sample components dissolved in the supercritical fluid crystallizing near the valve outlet as a result of pressure drop. This caused blockages, which resulted in pressure instability. Remembering his days as a student researching supercritical fluids, Yasuhiro Funada, now an engineer for LC instruments at Shimadzu Corporation recalled: "We spent just as much time troubleshooting as performing experiments."

Not only was the large volume of the needle valves used prior to this project preventing pressure stability, which generated pressure fluctuations, but the structure of the valves also made it easier for precipitated components to become clogged. Therefore, a valve with a smaller volume and completely new structure was required. Initially, Iwata contacted valve manufacturers outside of Japan, but not one said they could make the part.

Iwata therefore declared: "If that is the case, let's make it ourselves," and asked Shimadzu's Technology Research Laboratory to develop a valve. Hiroomi Goto, a third-year employee, was assigned to the project.

In order to acquire accurate data and increase reliability, we needed to create a valve with a smaller volume and produce constant pressure without clogging. To accomplish this mission, Goto and his research team produced many sketches.

Yasuhiro Funada

Yasuhiro FunadaDeputy Manager of the Instrument Development Group, LC Business Unit

After a number of meetings, Goto said to Iwata, "We have thought of all sorts of things, but I think a ball valve design is the most achievable. We have experience using ball valves as a check valve for LC applications, so it probably won't require a long development time."

However, Iwata gave an unexpected response.

"That's fine, but what about that other idea? Even if it takes longer to develop, would you please at least try it?"

The "other idea" that he was referring to was a type of valve called a diaphragm valve. The design is similar to a pair of pliers pinching a hose, so there is no extra volume involved, whether or not pressure is applied. Goto got the idea from the adjustment knob on the IV tube used at the hospital where his daughter was receiving treatment. The simplicity of the "pinch and release" design was perfect for an SFC valve. Though there was no assurance of it working, success would mean that an ideal and completely new valve structure would be achieved.

Once the valve was nearly finished, two sample valves were taken to Osaka University for testing. The results showed that the ball valve design also reduced pressure fluctuations, but that the diaphragm design provided even better performance. In fact, the pressure fluctuations dropped to one tenth the level of the existing product.

Associate Professor Bamba expressed his joy by saying: "Who would have thought that we could achieve such a great result in only one year!"

As if to validate the result after the valve design was basically decided, the SFC development project was selected as a Program for the Development of Systems and Technology for Advanced Measurement and Analysis, sponsored by the Japan Science and Technology Agency (JST). That accelerated the development process and, in 2013, the first prototype system was completed. This was followed by the development of an integrated analysis system that included SFE capability, which resulted in completion of a prototype close to the final product in 2014. When trial operations were performed, the dramatically superior performance of the system surprised even those involved in its development.

Hiroomi Goto

Hiroomi GotoTechnology Research Laboratory

A System That Simplifies Analysis

On January 27, 2015, the new Nexera UC supercritical fluid analysis system, combining both SFE and SFC technologies, was jointly announced by JST, Osaka University, Kobe University, Miyazaki Prefecture, and Shimadzu Corporation. Previously, attempting to analyze residual pesticides using an LC system would have required 15 pretreatment steps, but using SFE requires only 4 steps, due to the high sample solubility.

"Many customers are struggling with pretreatment, so they have great hopes for this system as a solution to those issues. Since its release, we have received many inquiries, even from customers that are not currently using Shimadzu LC products. By offering customers a solution that is not available from anyone else, we might succeed in changing their business practices. That makes me happier than anything else," Tomita, BU General Manager.

This technology may change the conventional wisdom about analysis.

Masami Tomita

Masami TomitaGeneral Manager of the LC Business Unit

Nexera UC That Is Expected to Fundamentally Change Conventional Wisdom About Analysis by Using Supercritical Fluids

* Affiliates and titles of the persons in this article are current as of the time of reporting.

Copied

Copied