Development of e-Hydro, a Motorized Hydraulic System Underpinning the Conversion of Commercial Vehicles to Electric Vehicles

With the aim of achieving carbon neutrality, the Japanese government declared that all new passenger vehicles sold nationally will be electric vehicles by 2035. At present, the conversion of passenger vehicles to electric vehicles is proceeding at a rapid pace, and this wave is now advancing on commercial vehicles such as cranes and garbage trucks. e-Hydro, Shimadzu’s motorized hydraulic system, was newly developed with its hydraulic technology, and is essential for the future evolution of commercial vehicles to electric vehicles.

Hydraulic Equipment Moves Big Things with a Small Force

Hydraulic equipment moves machinery by conveying electric power via oil flow and pressure, using pumps and valves. Their most important characteristic is that they can move big things using a small force. They utilize Pascal’s theorem, which states that if pressure is applied to part of a fluid at rest in an airtight container, the pressure will propagate evenly to all parts of the fluid.

This is easily seen in the raising and lowering of a forklift. The reason that a small vehicle can raise a ton or more of cargo is that it is equipped with hydraulic equipment. This equipment is also used in excavators and other construction machinery, as well as agricultural machinery, and garbage trucks, and demand has grown in step with industrial development. Hydraulic equipment is truly the “unsung hero” supporting the foundations of society.

e-Hydro, a Glimpse into the Future of the Conversion of Commercial Vehicles to Electric Vehicles

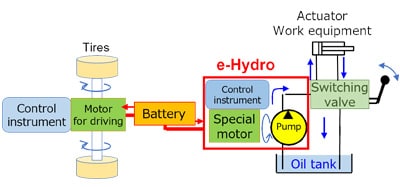

e-Hydro, the motorized hydraulic system developed by Shimadzu, is a total system combining a quiet hydraulic pump with a newly developed special motor and control equipment. e-Hydro operates when garbage trucks collect trash and when cranes raise and lower cargo.

When commercial vehicles are converted to electric vehicles, the hydraulic pump’s conventional source of power, the internal combustion engine, is eliminated by installing an electric motor instead. In an electric motor, electric power is supplied by batteries. Therefore, a highly efficient, motorized hydraulic system is required to extend the operating life of the motor.

Daisuke Goshima, Manager, Research & Development Department, Fluidics Systems Division

Accordingly, with e-Hydro, a special motor was developed to operate the hydraulic pump. Daisuke Goshima, Manager, Research & Development Department, Fluidics Systems Division, notes that “Controlling the power becomes extremely difficult when the power source is changed from an engine to a motor. Knowledge of new electronics becomes necessary, which means a more challenging work for us who specialize in machinery design. Not only the R&D department but also the sales department and production department pulled together to undertake the creation of e-Hydro.”

Development team with the e-Hydro (photo center) motorized hydraulic system.

Goshima is in the top row at far left.

“e-Hydro development is still only a work in progress. Firstly, in Japan, we will accumulate a track record of introducing this technology in commercial vehicles, such as cranes and garbage trucks, and add improvements. Then, we would like to develop e-Hydro globally for new markets including construction machinery, which is steadily being converted to electric motors. The next-generation mobility sector is evolving daily, but there is ample room for the utilization of hydraulic technology cultivated to date by Shimadzu. I would like to see us continue with the process of development, with the aim of developing new markets and solving the issues facing our customers.”

Achieving Low Noise and Vibration in Support of Workers

Hydraulic equipment production line within Seta Works (Otsu City, Shiga Prefecture), Shimadzu Corporation

Additionally, for electric vehicles to run quietly, the hydraulic pump must be quiet to ensure that vibrational noises are inconspicuous during operation. Usually, pulsations are produced when the two gears built into hydraulic pumps mesh, resulting in noise and vibrations. The newly developed e-Hydro incorporates SERENADE Technologies, a proprietary technique for achieving low noise levels in Shimadzu pumps. This enables the noise level to be reduced at night or in the city, where vibrational noise during operation is conspicuous.

In this way, e-Hydro will contribute to the realization of a quiet and comfortable working environment, as the conversion of commercial vehicles to electric vehicles continues.

Comments from a Development Engineer of e-Hydro

The design of e-Hydro combines a hydraulic gear pump with a control device containing a special motor and control software. Customization utilizing Shimadzu’s expertise in hydraulic technology, cultivated over many years, has led to the provision of operability and efficiency, with space savings and minimal power consumption now on par with vehicles with internal combustion engines. We are contributing new value while improving e-Hydro in line with the needs of the market and our customers, as we take initiatives to resolve issues in conjunction with our customers and suppliers.

Page Title and URL Copied.

Page Title and URL Copied.