UV-2600i Plus/UV-2700i Plus - Features

UV-Vis Spectrophotometer

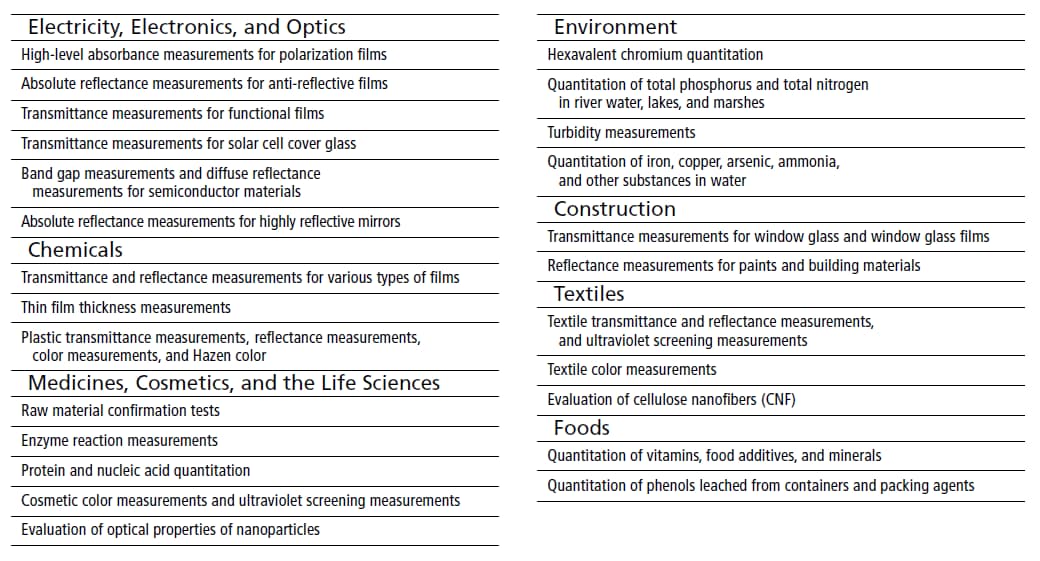

Perfect for a Wide Variety of Applications

The functionality of the UV-2600i Plus /2700i Plus can be freely expanded to suit the measurement objective. By accommodating a wealth of accessories, the system can address any user’s applications and a variety of situations. Thanks to intuitive operations, anyone can easily obtain the data required.

Single monochromator UV-2600i Plus

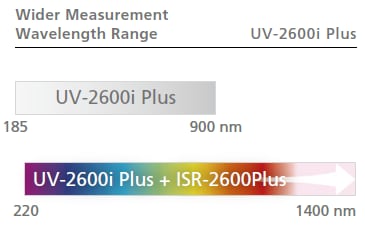

A key feature of the UV-2600i Plus equipped with a single monochromator is its measurement wavelength range. By using the optional ISR-2600Plus Integrating Sphere attachment, the measurement wavelength range can be extended from 220 nm to 1400 nm, significantly expanding its applications.

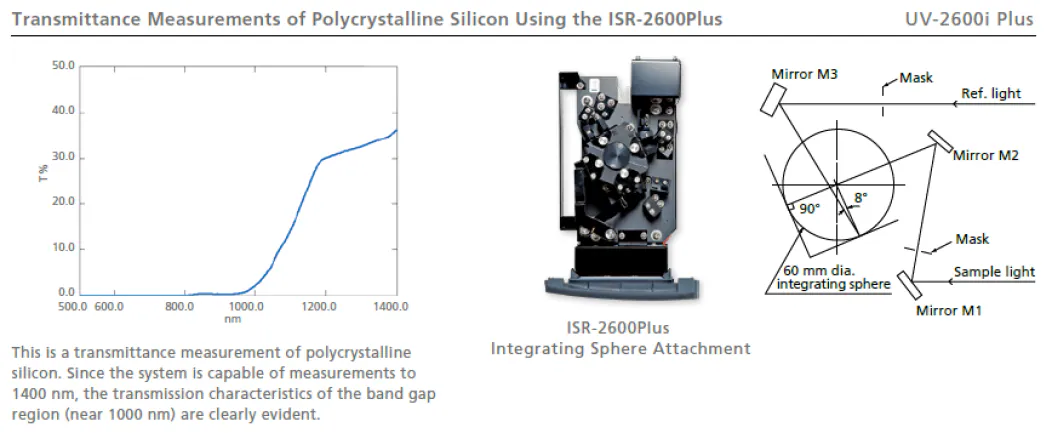

Integrating Sphere Enables Measurements to 1400 nm

The UV-2600i Plus is equipped with Shimadzu's proprietary LO-RAY-LIGH™ grade diffraction grating, which achieves high efficiency and low stray light levels. By installing the ISR-2600Plus two-detector integrating sphere, the 300 nm to 1100 nm wavelength range of conventional models can be extended to 1400 nm. In addition, the UV-2600i achieves a significant noise reduction, and can accommodate measurements of solar cell anti-reflective films and polycrystalline silicon wafers.

Measures Slight Differences in Absorbance

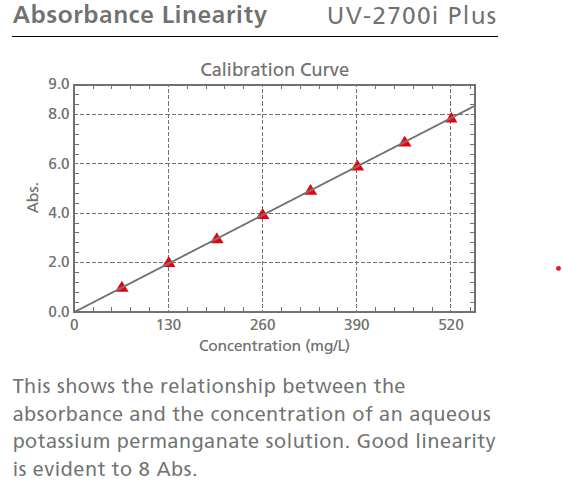

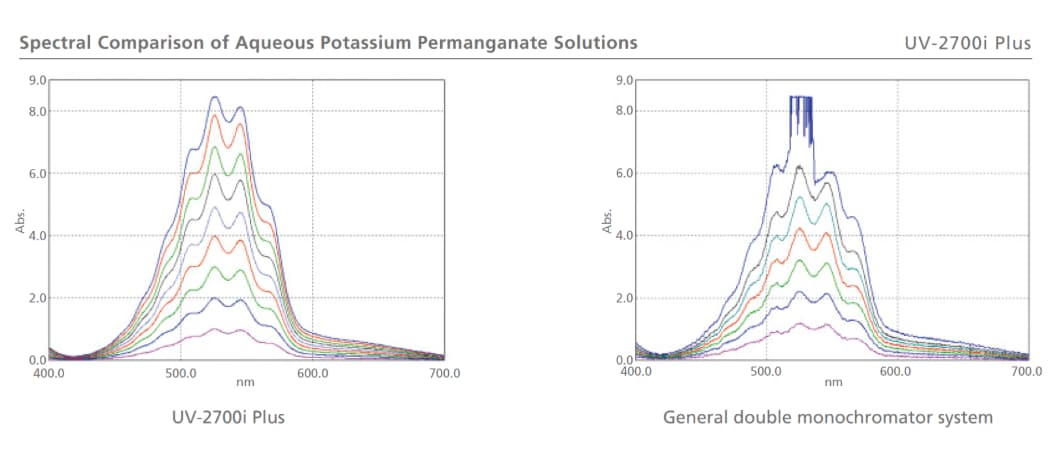

Equipped with a double monochromator that achieves ultra-low stray light levels, the UV-2700i Plus is optimal for measuring low transmittance samples, such as polarization films used for LCD panels. The UV-2700i Plus is capable of 8 Abs measurements, and can make accurate transmittance measurements to 1 part in 100 million, accommodating a variety of sample measurements.

Achieves Ultra-Low Stray Light, Enabling 8-Abs Measurements

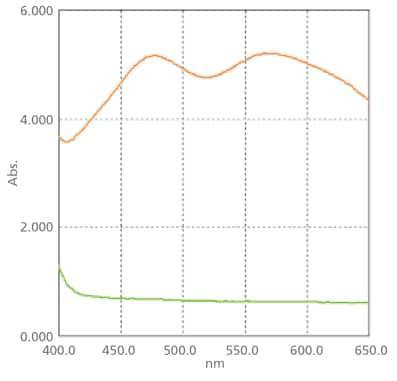

In the case of a device equipped with a general double monochromator, the absorbance that can be covered is about 5 to 6, but the UV-2700i Plus offers a range to 8 Abs, with a transmittance value of 0.000001 % (1 part in 100 million). This system achieves high-level absorbance measurements with incomparable precision. In addition to measuring even high-concentration samples as is, eliminating the need to dilute samples, the system can be applied to evaluating the transmission characteristics of polarization films. Wavelengths in the 400 nm to 650 nm range can be measured to 8 Abs.

Sample Polarization Film Measurement

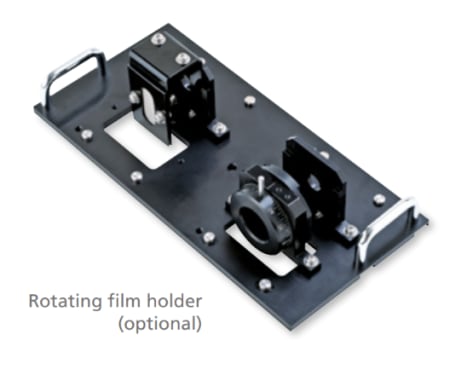

With the rotating film holder (image below), two film samples can be set on the same optical axis. In this example, the polarization film is rotated in the plane, and the transmittance is measured when the film transmits and blocks light.

Enables Compliance with ER/ES Regulations and Stronger Data Management

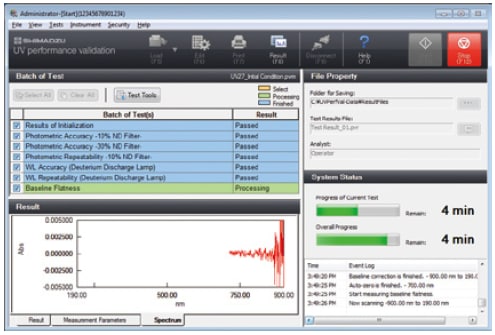

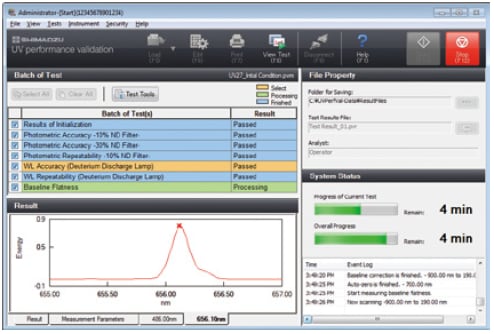

Compatible with Validation from PC Software

Validation can be implemented with PC software using UV validation software. In addition to simplifying daily inspections, this makes instrument performance checks and records management easier, enabling more secure regulatory compliance.

-

• The inspection parameters can also be saved to separate files for periodic and routine inspections and then called up for use. -

Note: Optional validation software is required to support the US Pharmacopeia and European Pharmacopeia.

Support for FDA 21 CFR Part 11, PIC/S GMP Guidelines and Other Regulations and Guidelines

Ensuring the integrity of data (database management), including the user management, user authority management, and data audit trails required for compliance with FDA 21 CFR Part 11, PIC/S GMP guidelines, and other ER/ES regulations is possible.

Option Software Assists with Regulation-Compliant Validation

UV validation software assists with performing the measurements and calculations required for validation. The software is included standard with UV-2600i/2700i models. In addition to routine inspections, it can also be used to perform instrument validation that is compliant with Japanese, US, and European pharmacopoeias.

What is Instrument Validation?

Instrument validation is an essential process for assessing and managing instrument health. What are the key elements of validation and how should they be performed? For more details, refer to the explanation page.

Checks whether or not baseline correction, auto zero correction or cell blank correction has been performed and informs the user if it has not been.

Checks whether or not baseline correction, auto zero correction or cell blank correction has been performed and informs the user if it has not been.

Informs the user if the last correction performed is not appropriate for the planned measurement. Informs the user if the UV-1900i Plus is not ready to begin measurement and when starting measurements

Informs the user if the UV-1900i Plus is not ready to begin measurement and when starting measurements

and 100 %T (0 Abs) corrections.

*1 This function can be enabled/disabled.

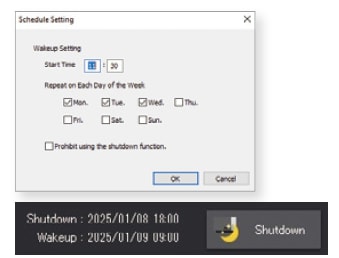

Shutdown/Wakeup Functions

The instrument can be shut down, and put into sleep mode. Putting the instrument into sleep mode limits power consumption and helps preserve the lamp. After a long period of measurements, the instrument and software can automatically be shut down. After shutdown, the instrument can also be set to wake up automatically at a specified time. With this function, analysis can start the instant the user arrives at the laboratory.

SolidSpec, TMSPC, LabSolutions, the Analytical Intelligence logo, LO-RAY-LIGH and PPSQ are trademarks of Shimadzu Corporation or its affiliated companies in Japan and/or other countries.

Excel, Microsoft and Azure are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Amazon Web Services and AWS are trademarks of Amazon.com, Inc. or its subsidiaries.

Google Cloud Platform and GCP are trademarks of Google LLC.