Initiatives for Building a Carbon-Free Society

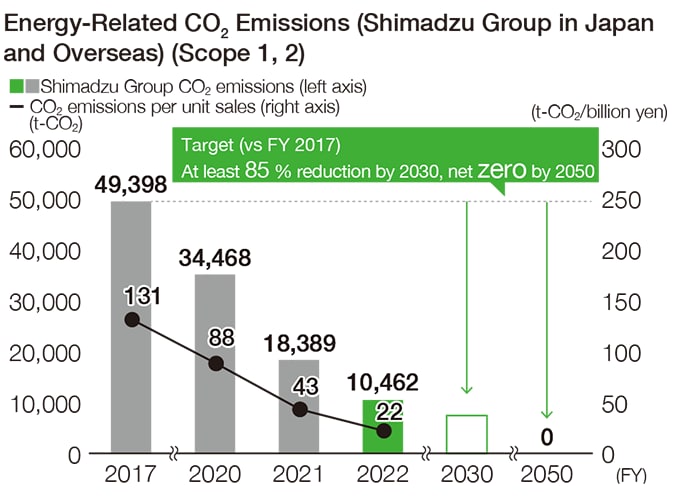

In April 2022, the Shimadzu Group set a target to achieve net-zero CO2 emissions from business activities by 2050,and is strengthening its efforts. Our interim targets are at least 85% reduction in 2030 and at least 90% in 2040 compared to FY2017. We have also set a target of reducing CO2 emissions from the use of Shimadzu products at customer sites, which account for at least 70% of CO2 emissions by other companies related to Shimadzu Group activities, by at least 30% in FY2030 compared to FY2020. The CO2 emission reduction target above for FY2030 was approved as the“ 1.5° C level” of Science Based Targets (SBT) in November 2022.

In March 2021, the Shimadzu Group joined the RE100 Initiative and switched to using electricity generated from renewable energy sources (“renewable energy”) at all major Shimadzu locations within and outside Japan. As a result, 85% of the Group’s total electricity consumption in FY2023 was generated from renewable energy sources.

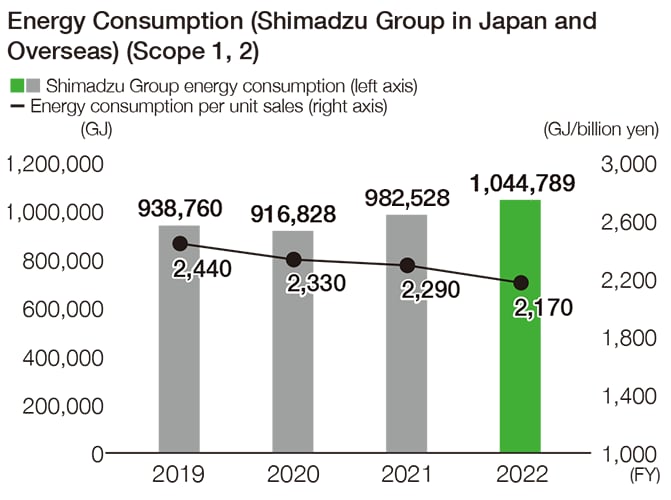

In FY2023, energy consumption by the Shimadzu Group within and outside Japan decreased 9.8% from the previous year to 951,016 GJ, due to initiatives for saving energy and other measures, which improved emission intensity by 15.1% to 1,858 GJ/billion yen. On the other hand, CO2 emissions increased 8% from the previous year (78.2% decrease versus the reference year (FY2017)) to 10,778 t-CO2. This increase was mainly due to the establishment of Shimadzu Diagnostics Corporation as a consolidated subsidiary. CO2 emissions per unit sales were 21 t-CO2/billion yen.

In addition to implementing measures based on the knowledge gained from installing smart meters and diagnosing energy usage, we will also install solar power equipment and use renewable energies to continue contributing toward building a carbon-free society.

- Reduce CO2 emissions from Shimadzu Group business activities to net-zero level by FY 2050.

- As interim targets, reduce CO2 emissions from Shimadzu Group business activities by at least 85 % by FY 2030 and at least 90 % by FY 2040,

- from FY 2017 levels.

- Reduce CO2 emissions from customers using the products sold by the Shimadzu Group by at least 30 % from FY 2020 levels, by FY 2030.

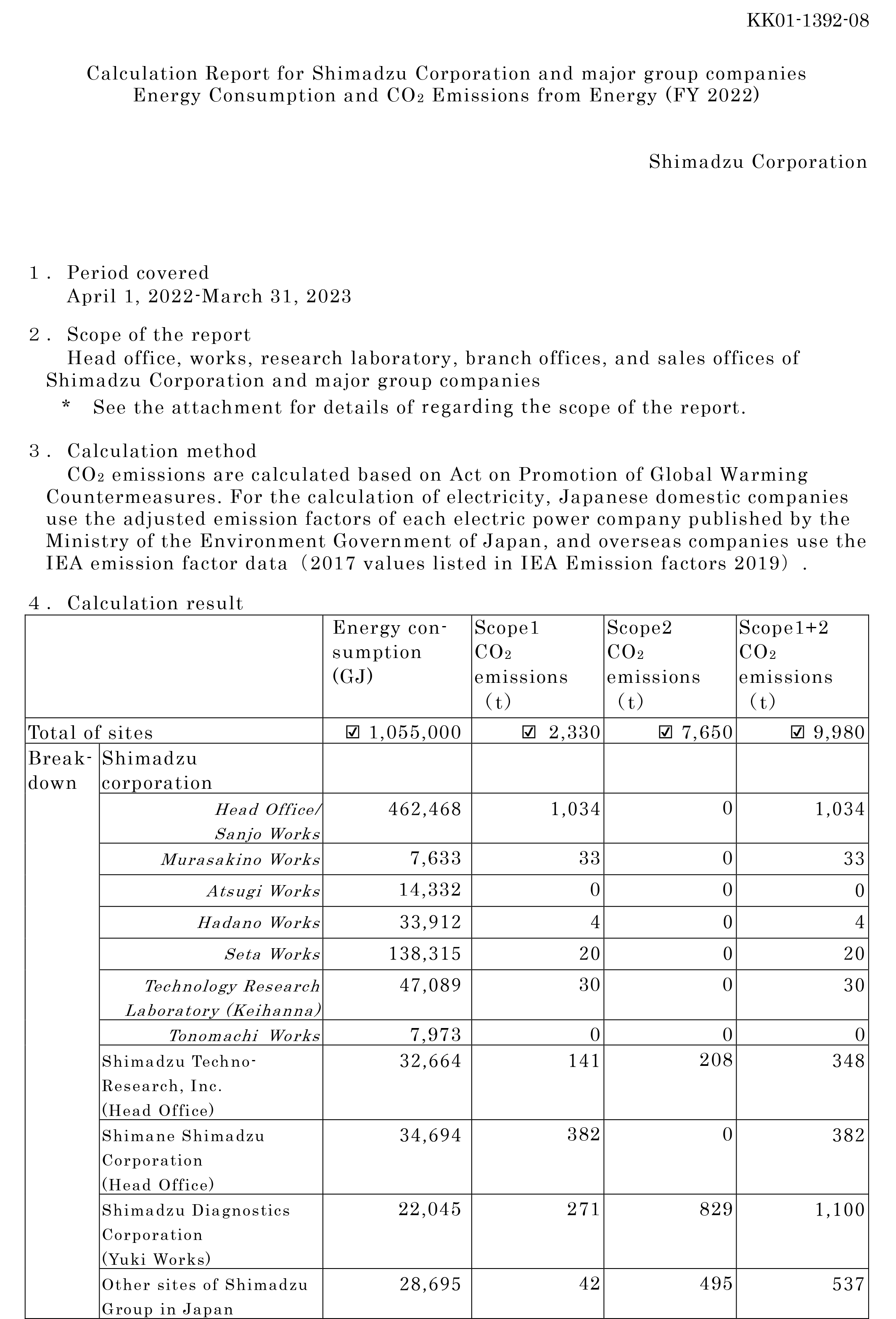

Third Party Assurance of Environmental Data

Shimadzu Corporation received a third-party assurance from Deloitte Tohmatsu Sustainability Co., Ltd., to disclose highly reliable environmental impact data.

[Assurance coverage]

Period covered: April 1, 2022 to March 31, 2023

Scope of the report: Head office, works, research laboratory, branch offices, and sales offices of Shimadzu Corporation and major group companies

Scope and Extent: energy consumption (GJ), location-based Scope 1 and 2 emissions (t-CO2)

- *Click on the image to view the PDF.

Calculation Report for Shimadzu group companies

Energy Consumption and CO2 Emissions from Energy

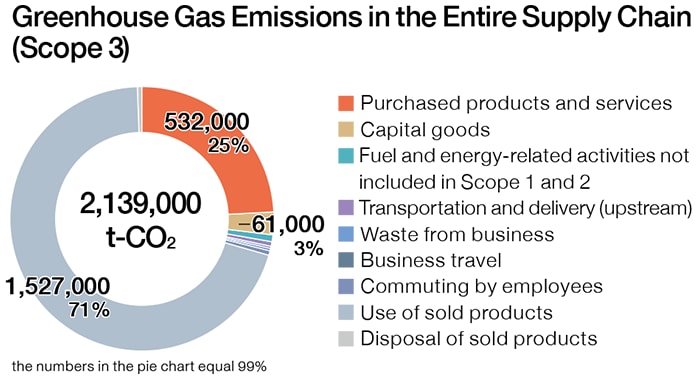

GHG emissions in the supply chain (By category)

Unit : thousand tons-CO2

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |||

|---|---|---|---|---|---|---|---|

| Scope 1 | Emissions | 3 | 2 | 2 | 2 | 3 | |

| Scope 2 | Emissions (market-based) | 36 | 32 | 16 | 8 | 8 | |

| Scope 3 | 1 | Purchased Goods and Services | 459 | 447 | 484 | 560 | 532 |

| 2 | Capital Goods | 11 | 14 | 14 | 63 | 61 | |

| 3 | Fuel and Energy-related Activities | 7 | 7 | 6 | 1 | 2 | |

| 4 | Upstream Transportation and Distribution | 5 | 5 | 6 | 9 | 8 | |

| 5 | Waste Generated in Operations | 2 | 2 | 2 | 2 | 1 | |

| 6 | Employee Business Travel | 4 | 1 | 2 | 2 | 3 | |

| 7 | Employee Commuting | 4 | 4 | 4 | 4 | 4 | |

| 8 | Upstream Leased Assets | 0* | 0* | 0* | 0* | 0* | |

| 9 | Downstream Transportation and Distribution | 3 | 3 | 0* | 0* | 0* | |

| 10 | Processing of Sold Products | 0* | 0* | 0* | 0* | 0* | |

| 11 | Use of Sold Products | 1,714 | 1,671 | 1,578 | 1,547 | 1,527 | |

| 12 | End-of-Life Treatment of Sold Products | 1 | 1 | 2 | 2 | 2 | |

| 13 | Downstream Leased Assets | 0* | 0* | 0* | 0* | 0* | |

| 14 | Franchises | 0* | 0* | 0* | 0* | 0* | |

| 15 | Investments | 0* | 0* | 0* | 0* | 0* | |

- *0 means less than 500ton.

Cat11 is estimated based on the hypothesis, our products would be used for 10 years by customer.

Reducing CO2 Emissions from Logistics

We are also engaged in measures to reduce CO2 emissions during shipment, up to the point that products are delivered to the customer.

By improving the truck loading rate and promoting a modal shift, Shimadzu Logistics Service Corporation has reduced CO2 emissions by about 100 tons or more since fiscal 2011.

Primary activities include mixing shipments to optimize utilization of trips between locations, consolidating smaller freight shipments into chartered shipments, consolidating freight from regular commercial routes into chartered shipments, shifting freight modes to rail or ship, and shifting package with wood to reinforced cardboard.

The transport system is used to share information about transporting goods between different divisions, so that the above measures can be implemented more efficiently within daily operations.

For export shipments, an in-house bonded warehouse area has been used to process customs without the need to transport items by truck. After clearing customs, items are transported by low-emission shuttle trucks (running on natural gas) to airports or seaports. Shipping containers are reused for shipping both exports and imports. Hybrid work vehicles are also being introduced.

Shuttle freight to airport

Package with reinforced cardboard

Reducing Energy Consumption in IT Environments

Shimadzu Business Systems Corporation, which manages various Shimadzu Group servers, is reducing power consumption by migrating to virtual servers. Virtual servers use server resources more efficiently by establishing multiple server environments within a single physical server. Using virtual servers not only reduces electrical power consumption, but also can save space and reduce expenses. Consolidating 21 servers into 10 servers in FY 2016 has reduced power consumption by an estimated 32,850 kWh per year.

Diagram of Switching to Virtual Servers

Installation of task light

As part of power-saving measures after the Great East Japan Earthquake in FY 2011, we have been deploying measures to reduce ceiling lighting and install task-ambient lighting that illuminates only the immediate work area.

Environmental Considerations for New Construction Materials

The Head Office building within the Sanjo Works site incorporates a variety of environmentally-friendly features, such as a passive ventilation system, natural and artificial lighting sensors, radiant air conditioning systems, and active use of local wood materials sourced from within Kyoto Prefecture.

In terms of the Kyoto standards for the Comprehensive Assessment System for Built Environment Efficiency (CASBEE), which also evaluates buildings based on how well they typify Kyoto, the building earned an "S" score, which is the highest available.

The Quality Center at Sanjo Works and the South Building No. 1 at Seta Works were insulated and lighting in all office areas was converted to LED lighting. In addition, they were designed and built for energy efficiency with high-efficiency air-conditioning and transformer systems.

Head Office building at Sanjo Works

The Quality Center at Sanjo Works

the South Building No. 1 at Seta Works

Efforts are also being made to reduce CO2 emissions and electricity usage at Shimadzu Group companies, such as installing solar panels and LED lighting. At the production location in Malaysia, power generated from solar panels installed in April 2019 accounts for about 25 to 30 % of the electricity consumed. Environmental measures were implemented at the production location in Shimane as well, such as by installing solar panels on all three buildings.

Shimadzu Manufacturing Asia Sdn. Bhd.(Mlaysia)

Shimane Shimadzu Corporation

(Shimane, Japan)