Evaluating Specific Manufacturing Processes

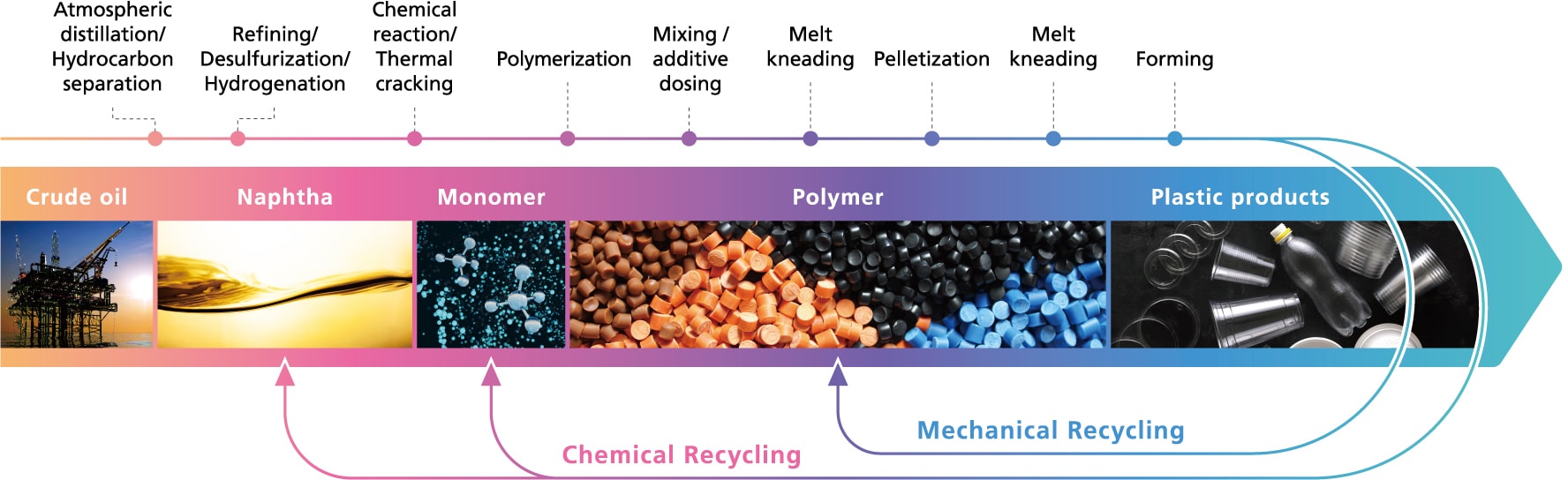

Plastics are manufactured using a wide variety of processes. To ensure appropriate manufacturing parameters are specified for each process, manufacturers need to understand the status of each material. For plastics, the material status varies for each manufacturing process and establishes which material properties need to be determined. Some evaluation methods that can vary depending on the material status and manufacturing process are listed below.

| Manufacturing Process | Evaluation Category | Evaluation Subcategory | Instrument |

|---|---|---|---|

| Atmospheric Distillation (Component Separation) | Component analysis, sulfur content | GC | |

| Purification, Desulfurization, Hydrogenation | GC | ||

| Chemical Reaction, Pyrolysis | GC | ||

| Polymerization | Polymer analysis | Composition analysis | FTIR, Raman, PY-GC/MS, MALDI |

| Chemical structural analysis | FTIR, Raman, MALDI, LC/MS | ||

| Physical structural analysis | FTIR, Raman, SPM | ||

| Adding Additives | Additive component analysis | Composition analysis of organic matter | FTIR, PY-GC/MS, LC/MS |

| Organic matter quantitative analysis | PY-GC/MS, LC/MS, MALDI | ||

| Inorganic matter composition analysis plus quantitative analysis | EDX, ICP-OES, ICP/MS, EPMA | ||

| Particle size measurement | Particle size analyzer | ||

| Pelletization | Molecular weight distribution | GPC | |

| Composition analysis | FTIR, Raman, PY-GC/MS, MALDI | ||

| Structural analysis | FTIR, Raman, MALDI | ||

| Ratio of each component in composition | TGA, FTIR | ||

| Moisture content | Moisture analyzer | ||

| Molding | Rheological evaluation | Viscosity evaluation | Capillary flowtester |