Chemical Substances Management

Shimadzu uses a wide variety of chemical substances for manufacturing, R&D, application development, and other activities. Handling these improperly could cause an incident or accident and many are governed by a variety of laws and regulations.

Therefore, through cooperation between the departments in charge of legal and regulatory compliance and the departments using the chemical substances, Shimadzu makes sure the substances are managed appropriately in accordance with applicable laws and regulations. In addition, Shimadzu also ensures chemical substances are managed appropriately from a business continuity planning (BCP) perspective, such as by confirming that each department has applicable import/export licenses, conducts emergency response training for each item, and is making progress replacing hazardous substances with safer alternatives.

Also, the Chemical Registration Information System (CRIS) developed by Shimadzu System Development Corporation is used to control individual chemical agents entering and leaving the company. In addition to managing the quantities of chemical substances when they are purchased, used, and discarded, this system can also be used to calculate total inventory and usage quantities and quickly issue governmental reports required by PRTR (pollutant release and transfer register) laws.

Usage of PRTR-Reported Substances in Japan

Development of CRIS Chemical Management System

CRIS (Chemical Registration Information System) was developed in 2001 by Shimadzu Trustech Co., Ltd. (Shimadzu System Development at that time) in cooperation with the Faculty of Engineering, Kyoto University. To date, it has been adopted by more than 160 universities, research institutes and companies, including Kyoto University and Waseda University. CRIS offers a variety of optional software that is customized and upgraded to meet your needs (a screen example of risk assessment option on the right).

The left is an example of a CRIS inventory registration screen. GHS hazard marks (GHS: Globally Harmonized System of Classification and Labelling of Chemicals) and Safety Data Sheets (SDS) can be easily displayed at the time of drug registration.

Example of CRIS Screen, Chemical Management

Ozone depleting substances

In fiscal 2016, Shimadzu completely eliminated the use of hydrochlorofluorocarbons (HCFCs), an ozone-depleting substance, in the cleaning process during manufacturing.

Pollution Measures

Air Quality Measurements (Sanjo Works)

SOx and NOx levels in exhaust gases emitted from boilers used in factories are monitored regularly with respect to Shimadzu standards, which are stricter than the standards in Japanese air pollution laws and Kyoto prefectural environmental regulations.

At the Sanjo Works, aging fuel oil-fired boilers and natural gas boilers are being replaced successively to help prevent air pollution and to reduce CO2 emissions. In FY 2014, all of the fuel oil-fired boilers have been replaced.

Water Quality Measurements (Sanjo Works)

Plant effluents are regularly measured with respect to Shimadzu standards, which are stricter than the standards in Japanese wastewater laws and Kyoto city wastewater regulations. In addition to regular measurements of each water quality parameter, the Sanjo Works also utilizes a specialized monitor and intranet LAN to continuously monitor pH and TOC (total organic carbon) levels. Also, a rapid response system has been built to send email notification to the person in charge of the problem if the pH level of wastewater exceeds the Shimadzu standards.

In addition, the total organic carbon (TOC) in wastewater is constantly monitored at its main production sites, Sanjyo, Seta and Hadano Works, and its research and development sites, Technology Research Laboratory (Keihanna) and Shimadzu Tokyo Innovation Plaza. TOC is the total amount of carbon that constitutes organic matter in water and is one of the leading indicators of water quality. TOC Analyzer is ideal for upstream wastewater monitoring applications because it can detect organic pollutants very quickly. By disseminating many examples of its use in our company to the public, we hope to promote its use in the real world, and to support our customers' environmental efforts.

On-Line Total Organic Carbon Analyzer

Water Management

We are committed to reducing water usage by using rainwater to water green areas and by installing water-saved fixtures.

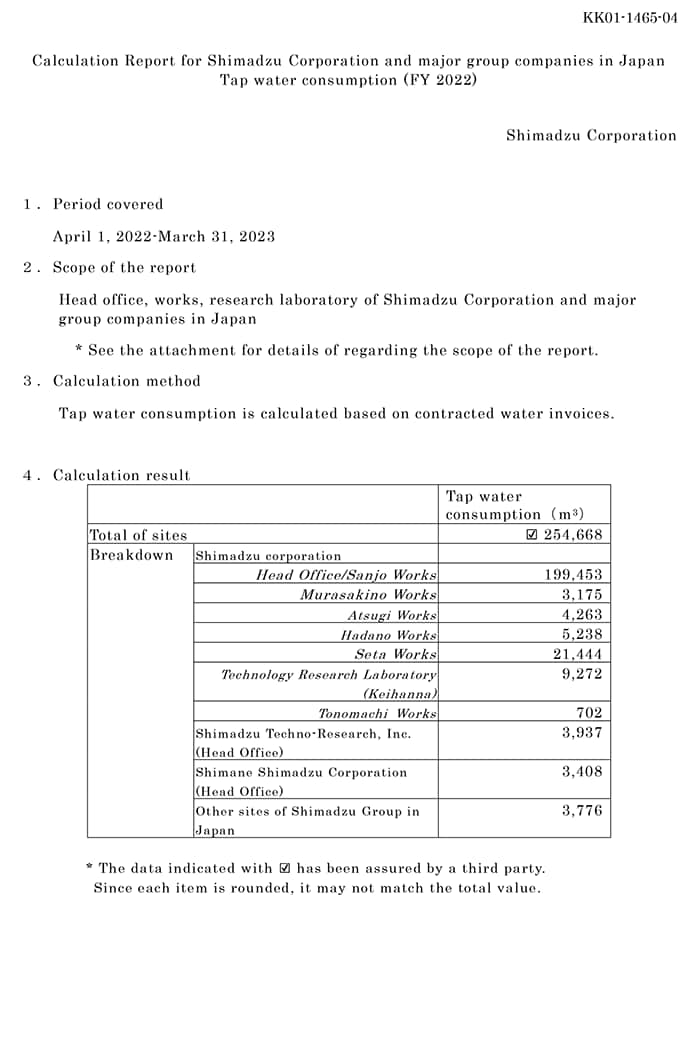

In FY 2022, water consumption at domestic production sites and laboratories increased by 23.8% year on year to 255,000 m3 due to increased production and other factors, and per unit of sales also worsened by 10.0% to 530 m3/billion yen.

Although we manage plant effluent under our own voluntary standards which are stricter than the standards required by current laws and regulations, there was one case at a Shimadzu factory last fiscal year where the effluent standard for n-hexane extract was exceeded.

We will continue to implement measures for using resources sustainably.

Third Party Assurance of Environmental Data

Shimadzu Corporation received a third-party assurance from Deloitte Tohmatsu Sustainability Co., Ltd., to disclose highly reliable environmental impact data.

[Assurance coverage]

Period covered: April 1, 2022- March 31, 2023

Scope of the report: Head office, works, research laboratory of Shimadzu corporation and major group companies in Japan

Extent:Tap water consumption(m3)

- *Click on the image to view the PDF.

Calculation Report Tap water consumption

Report on Effluent Violation

Shimadzu Corporation’s Seta Works (Otsu City, Shiga Prefecture) was notified by Otsu City that n-hexane extract exceeding the standard specified in the Sewerage Act had been detected in effluent discharged on July 25, 2022(standard 30 mg/L or less, detected 42 mg/L).

As a result of the investigation, the cause was identified as waste water discharged from the kitchen, and (1) a request was made to the kitchen supplier to take through measures to prevent contamination with oil etc., and (2) measures were taken to clean the pipes in the kitchen system, ant the results were reported to the City of Otsu. Subsequent follow-up monitoring has led to the establishment and operation of a monthly cleaning rule for the kitchen, which has rectified the issue.